Company

Shaoxing Lizhi Plastic Products Co., Ltd.

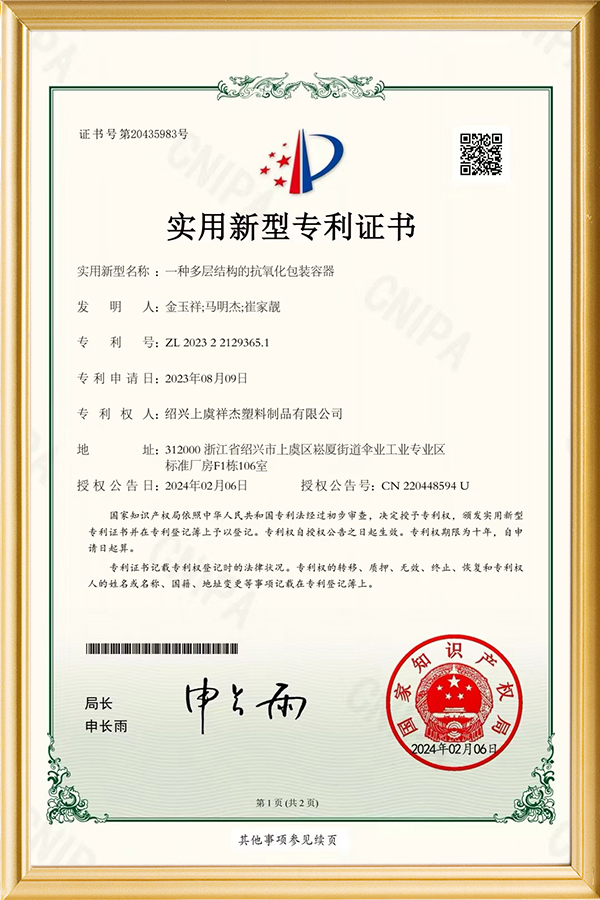

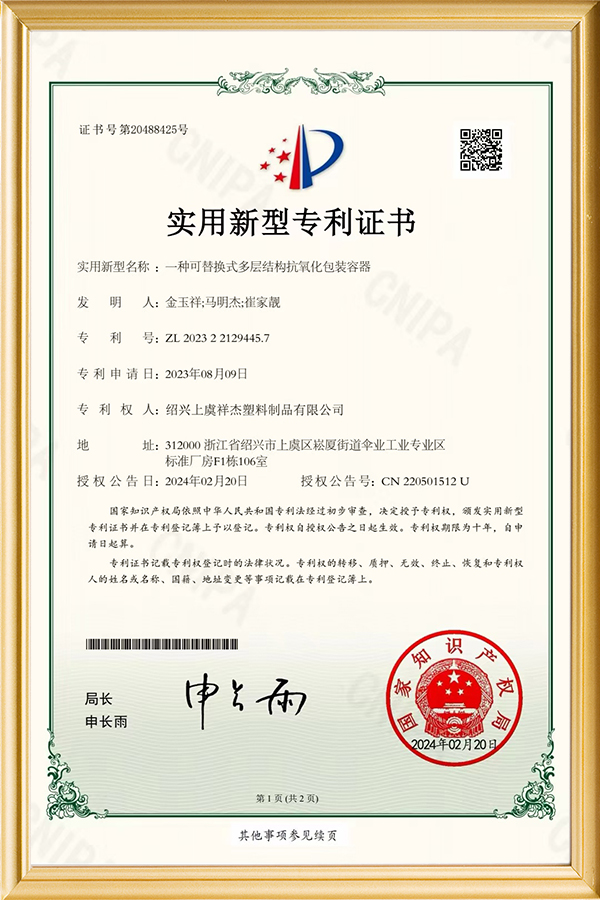

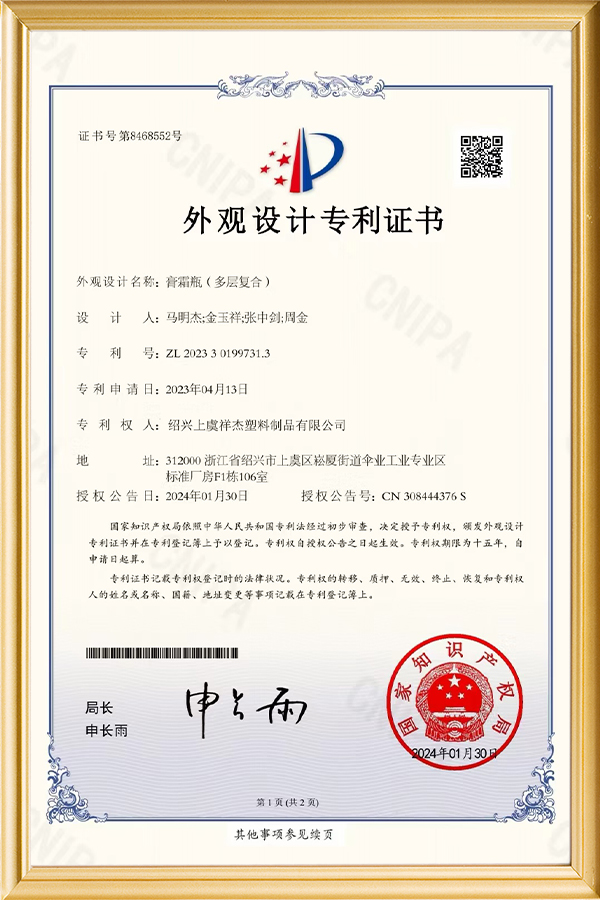

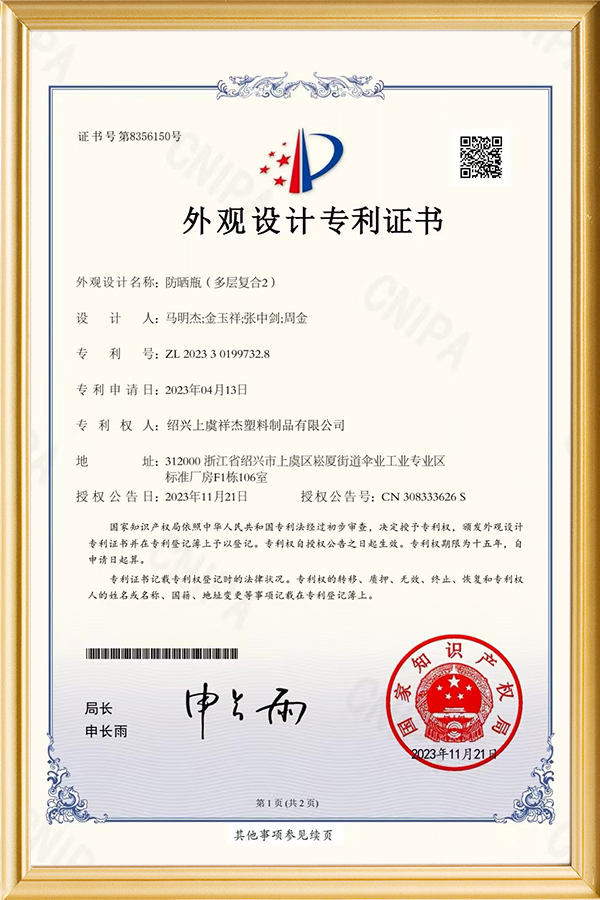

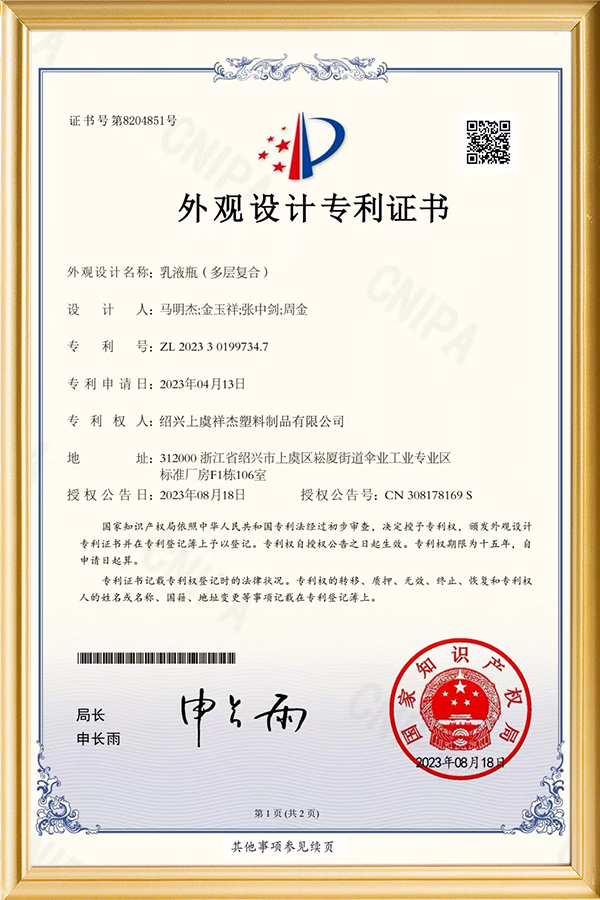

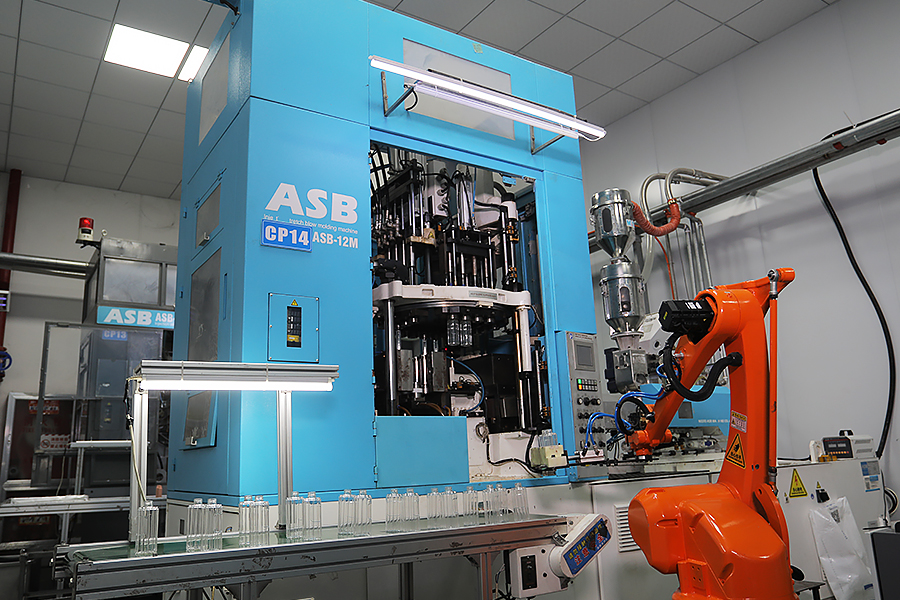

As a famous China Square Cleansing Bottle Manufacturers and Empty Square Cleansing Bottle Suppliers, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

Blow Molding Technology and Its Role in Manufacturing Square Cleansing Bottles

Blow molding is a versatile manufacturing process that involves heating plastic until it becomes pliable, extruding it into a tube (called a parison), and then inflating it within a mold to create a hollow shape. For Square Cleansing Bottles, this technology is used to produce a wide range of sizes and shapes with highly accurate designs. The process begins with the extrusion of a parison, which is a tube of plastic that is heated to a precise temperature to allow for uniform expansion when air is blown into it. This parison is inserted into a mold designed specifically to shape the Square Cleansing Bottle. The inflation stage is where the air is introduced into the parison, causing it to expand and form the desired shape. For Square Cleansing Bottles, blow molding ensures the production of sharp edges and clear lines, which are characteristic of the square design. This is particularly important in packaging where precision is key, as square bottles with smooth, crisp edges create an appealing and premium aesthetic that stands out on shelves. The consistent inflation allows for uniform wall thickness, providing the bottle with strength and durability while minimizing the risk of defects. After inflation, the bottle is cooled to solidify its structure, ensuring that it retains its shape and integrity. The cooling process ensures that Square Cleansing Bottles are not only visually attractive but also robust and capable of withstanding handling, shipping, and everyday use. Blow molding thus provides the ideal combination of precision, strength, and functionality required to meet the demands of the cosmetics industry.

Blow molding can be divided into two primary types: single-layer and multi-layer blow molding. Both types are used in the production of Square Cleansing Bottles, depending on the specific requirements of the cosmetic product being packaged. Single-layer blow molding, as the name suggests, involves the creation of a bottle using just one layer of plastic. This method is relatively simple and cost-effective, making it a good choice for mass production of bottles that do not require special barrier properties. For Square Cleansing Bottles, single-layer blow molding is used to create products where the visual appeal is the primary focus, and where the ingredients inside the bottle are not highly sensitive to exposure to light, oxygen, or moisture. One of the major benefits of single-layer blow molding is its cost-effectiveness. The process is simpler and requires fewer materials, which lowers production costs, making it a viable solution for producing high-quality yet affordable Square Cleansing Bottles. Single-layer blow molding provides flexibility in terms of design and customization. Manufacturers can experiment with various shapes, sizes, and color finishes, allowing brands to create packaging that aligns with their specific branding and marketing goals. For example, Square Cleansing Bottles can be customized with embossed logos or other aesthetic details, enhancing the bottle’s visual appeal and making it a standout feature on retail shelves. On the other hand, multi-layer blow molding is used when the cosmetic product inside the bottle requires additional protection from external factors such as oxygen, light, or moisture. Multi-layer blow molding involves the use of multiple layers of plastic, each with its own unique properties. For example, the outer layers of the bottle might be made from strong materials like PET, while the middle layer could be made from a barrier material like EVOH (Ethylene Vinyl Alcohol), which helps protect the product from oxygen. This is particularly beneficial for packaging high-end cosmetic products like serums, creams, or lotions, which require extended shelf life and need to be protected from environmental factors that could degrade their quality. Multi-layer blow molding offers enhanced protection for cosmetic formulations, ensuring that they remain fresh and potent over time. It also improves the structural integrity of the Square Cleansing Bottle, making it more resistant to impacts, bending, or cracking. As a result, multi-layer blow molding is ideal for packaging premium products that demand higher standards in both aesthetics and performance. By using this technique, Shaoxing Lizhi Plastic Products Co., Ltd. ensures that each bottle not only looks sophisticated but also offers superior functionality and longevity, making it the preferred choice for many leading cosmetic brands.

Blow molding technology is widely recognized for its cost-effectiveness and efficiency, particularly when it comes to producing large quantities of Square Cleansing Bottles. The process is designed to minimize material waste and reduce production costs, making it an attractive option for manufacturers looking to optimize their operations. By using precise control over the extrusion and inflation stages, blow molding allows for the efficient use of plastic, ensuring that material usage is kept to a minimum while still producing high-quality bottles. This makes it an ideal solution for producing Square Cleansing Bottles at scale, while also ensuring that each bottle meets the required standards of quality and performance. One of the key advantages of blow molding in terms of cost-efficiency is its ability to produce hollow products with uniform wall thickness. This eliminates the need for additional processes, such as trimming or finishing, that might be required with other manufacturing techniques. As a result, manufacturers can reduce labor costs and improve production speed, making it possible to produce large volumes of Square Cleansing Bottles quickly and economically. This is particularly important in the cosmetic packaging industry, where time-to-market is crucial, and brands need to keep up with ever-changing trends and consumer demands. Blow molding allows for a high degree of automation, which further increases efficiency and reduces human error. Shaoxing Lizhi Plastic Products Co., Ltd. takes advantage of this automation to streamline its production process, ensuring that each Square Cleansing Bottle is manufactured with high precision and at a lower cost. By using advanced machinery and automated processes, the company can deliver large quantities of bottles quickly, ensuring that clients receive their orders on time and within budget. This cost-effective approach enables cosmetic brands to access premium packaging without incurring high production costs, ultimately contributing to the success of their products in the competitive market.

One of the most significant benefits of blow molding technology is the durability and strength of the final product. Blow molding ensures that Square Cleansing Bottles are robust and able to withstand the challenges of handling, transportation, and regular use. The precision of the blow molding process guarantees that each bottle is produced with consistent wall thickness, enhancing its overall strength and resistance to impact. This is particularly crucial for products like Square Cleansing Bottles, which are often exposed to rough handling during shipping or everyday use by consumers. The strength of blow-molded Square Cleansing Bottles also makes them resistant to cracking or breaking, ensuring that the bottle maintains its integrity throughout its lifecycle. The ability to create bottles with uniform wall thickness means that the product is less likely to suffer from weaknesses or flaws that could compromise its performance. The precise control over the inflation process allows manufacturers to fine-tune the structural design of the bottle, making it more resilient to external forces. For the cosmetics industry, packaging durability is essential, as damaged bottles can result in wasted product and customer dissatisfaction. Shaoxing Lizhi Plastic Products Co., Ltd. understands the importance of creating packaging that not only looks elegant but also functions effectively. By utilizing blow molding technology, the company produces Square Cleansing Bottles that offer both aesthetic appeal and the strength needed to protect the cosmetic products inside. This ensures that the products remain safe, secure, and attractive to consumers, contributing to the success of the brand’s overall image and product experience.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français