Company

Shaoxing Lizhi Plastic Products Co., Ltd.

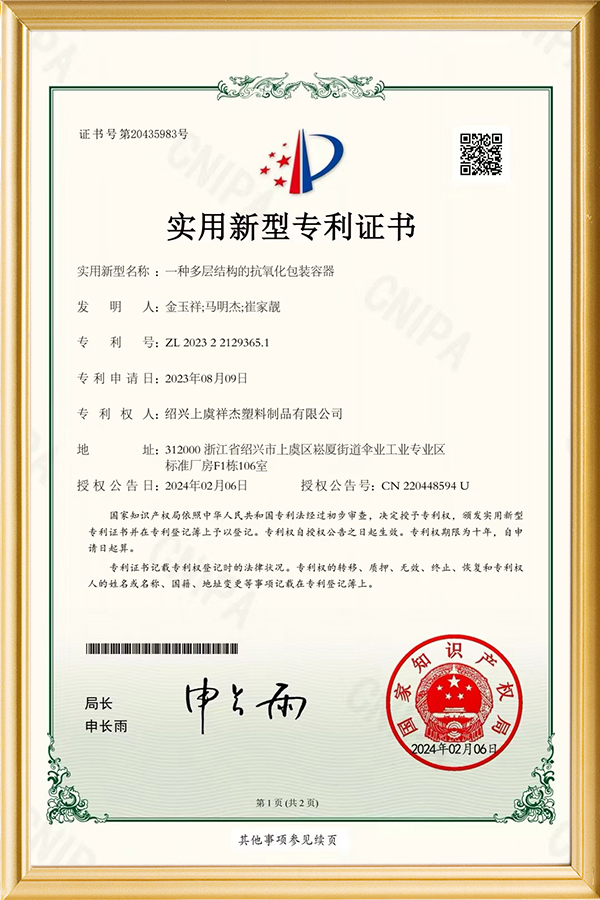

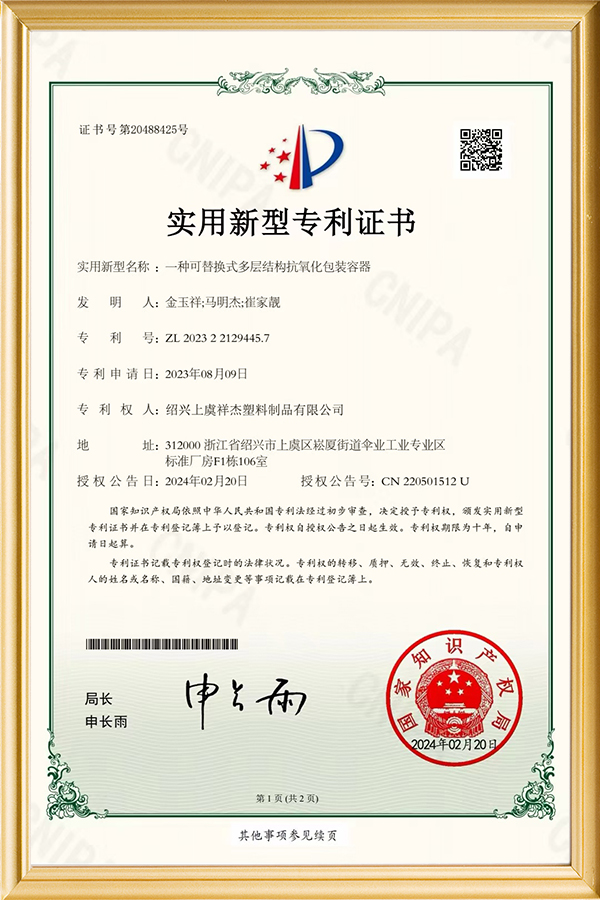

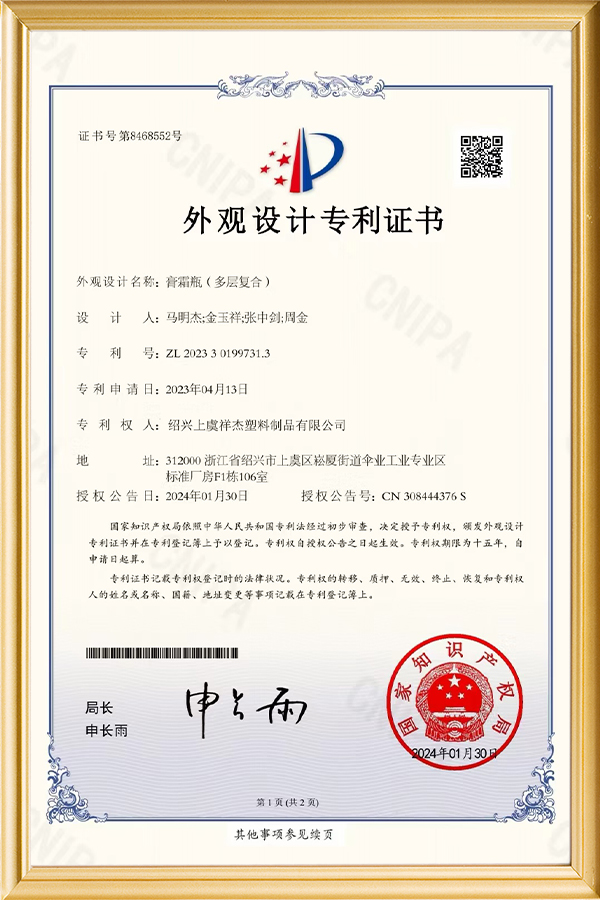

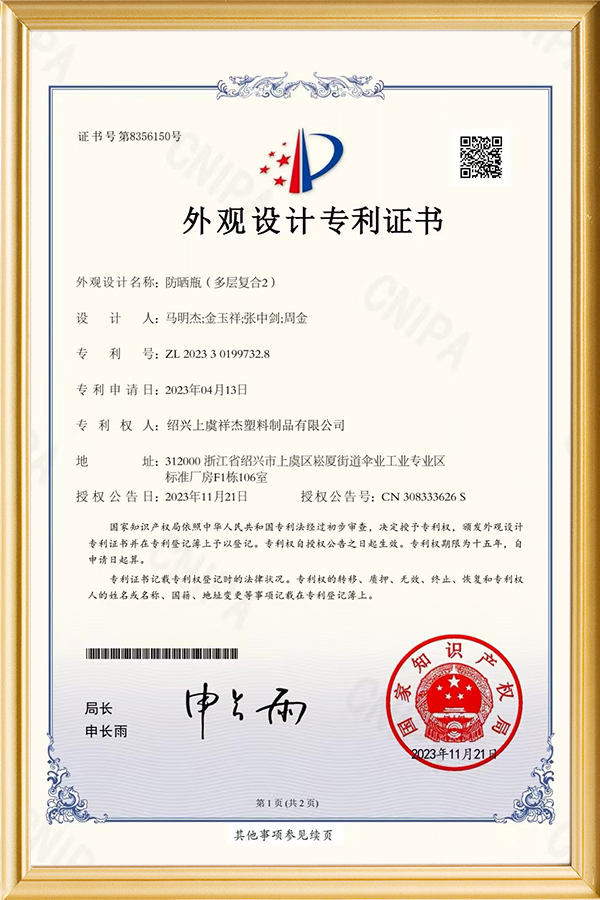

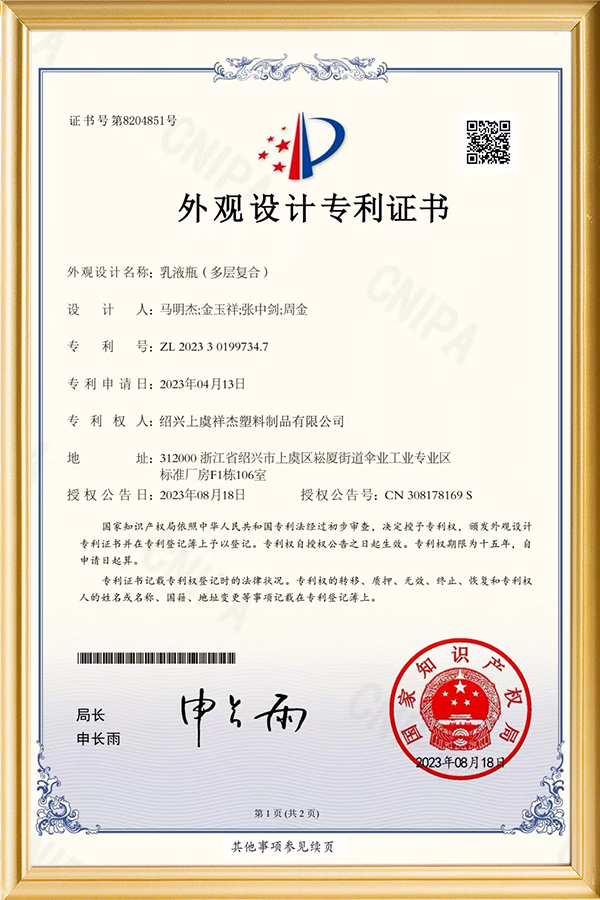

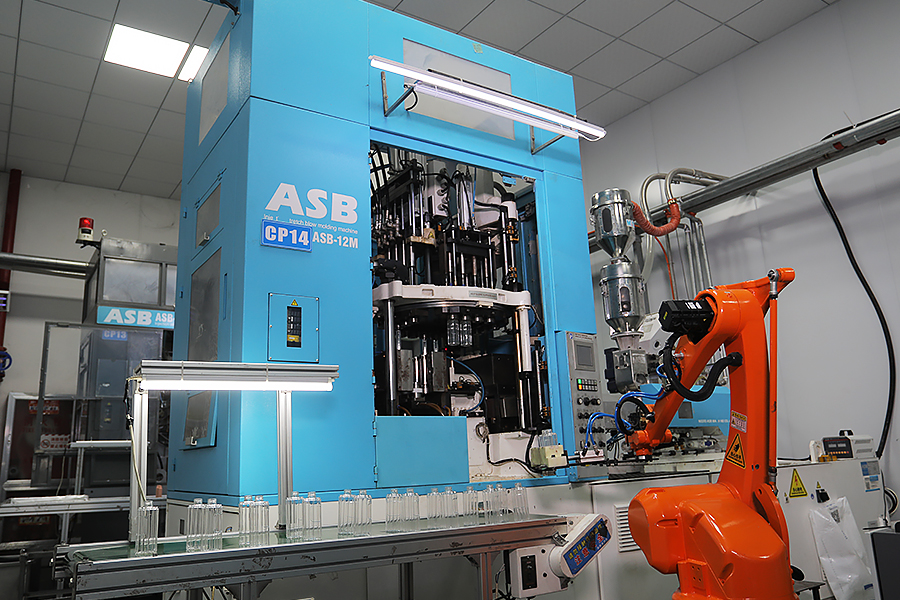

As a famous China Multi-layer Composite Bottle Series Manufacturers and Empty Multi-layer Composite Bottle Series Factory, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

Advantages of Multi-layer Blow Molding Technology

One of the most significant advantages of multi-layer blow molding technology is the creation of enhanced barrier properties. Packaging products, in the cosmetic, pharmaceutical, and food sectors, often need protection from environmental factors such as oxygen, moisture, light, and UV rays. These elements can degrade the quality and efficacy of the product inside, making it less effective, unsafe, or even harmful. Multi-layer blow molding allows manufacturers to layer different materials, each providing specific barrier protection to address these concerns. For example, one layer can be designed to block oxygen, which is a primary cause of oxidation in products like cosmetics and medicines. The outermost layer may be made from materials like polyethylene (PE) or polypropylene (PP), which offer durability and resistance to external damage. The middle layer can include materials such as ethylene vinyl alcohol (EVOH), which has excellent oxygen barrier properties, preventing oxygen from coming into contact with the product. EVOH is known for being a robust oxygen barrier, making it ideal for protecting sensitive formulations like sunscreens, lotions, and medicines that can lose their potency when exposed to oxygen. The middle or inner layers can also be designed to protect against moisture, which can be a cause of microbial growth or product separation, particularly in the food and cosmetics industries. Materials like PET (Polyethylene Terephthalate) or PETG (Polyethylene Terephthalate Glycol) are used to provide moisture resistance. The combination of different materials ensures that the final packaging solution can offer enhanced protection against all these environmental factors, thereby preserving the integrity and extending the shelf life of the product inside. As a famous China Multi-layer Composite Bottle Series Manufacturers and Multi-layer Composite Bottle Series Factory, Shaoxing Lizhi Plastic Products Co., Ltd. applies these advanced barrier technologies to create bottles that ensure the contents inside are protected from oxidation, moisture, UV light, and contamination. This layered protection is especially crucial in the cosmetics industry, where product efficacy depends on the stability of the ingredients.

Another major advantage of multi-layer blow molding is the ability to customize packaging to meet specific requirements. Traditional single-layer molding limits design flexibility, but with multi-layer technology, manufacturers can combine different materials, colors, textures, and functionalities into a single packaging solution. This flexibility enables brands to create packaging that not only provides optimal protection but also aligns with their branding strategies. Multi-layer blow molding allows for the integration of multiple layers with different functionalities, such as the use of opaque or tinted layers to block UV light while allowing the outer layer to feature high transparency or a custom design. This is especially important for the cosmetic industry, where packaging aesthetics play a significant role in attracting consumers. By using materials like PETG or PP, manufacturers can produce bottles that have the desired look and feel, with high clarity or a frosted finish, while also ensuring that the product remains safe from light degradation. The technology can enable the incorporation of a variety of dispensing features, such as pumps, twist tops, or spray nozzles, without compromising the packaging’s protective abilities. Shaoxing Lizhi Plastic Products Co., Ltd. utilizes this level of customization in its multi-layer composite bottles, offering clients the ability to tailor both the appearance and functionality of the packaging while maintaining a high level of protection for the product inside. The ability to incorporate different features into the same bottle also reduces the need for additional components, streamlining the packaging process and reducing the overall cost of production. As a result, brands can achieve greater flexibility and reduce packaging costs while still providing superior protection for their products.

Multi-layer blow molding technology enhances the overall structural integrity and durability of packaging. By using multiple layers of different materials, manufacturers can combine the strengths of each material to create a more robust and resilient packaging solution. The outer layers of multi-layer bottles are made from durable materials like PP or PE, which provide high impact resistance, scratch resistance, and the ability to withstand physical stress, including compression, squeezing, and dropping. The inner layers, which are typically designed for barrier properties, can also add to the bottle's durability by preventing internal pressure build-up from moisture or gas. This makes multi-layer composite bottles much more resistant to damage compared to single-layer bottles. For instance, if a bottle is dropped, the multiple layers of material help absorb the impact, reducing the risk of cracking or puncturing. This is particularly important for products that are handled frequently or transported over long distances. Shaoxing Lizhi Plastic Products Co., Ltd. takes advantage of this technology to create multi-layer composite bottles that are lightweight yet durable. By ensuring the structural integrity of the packaging, the company provides solutions that are not only functional but also capable of withstanding the rigors of storage, transport, and consumer use without compromising the safety or quality of the product inside.

One of the challenges in packaging design is achieving a balance between strength and weight. Traditional materials used in packaging may be either lightweight but fragile or strong but heavy. Multi-layer blow molding allows manufacturers to overcome this challenge by creating packaging that is both lightweight and durable. The technology enables the production of bottles that are strong enough to protect the product while maintaining a lightweight design, which is especially important for industries where transport efficiency and convenience are priorities. Shaoxing Lizhi Plastic Products Co., Ltd. uses multi-layer blow molding to create composite bottles that are lightweight without compromising strength. This is particularly beneficial for cosmetics and food products that require large quantities of packaging. By using lighter packaging, the overall transportation cost is reduced, and the environmental footprint of the packaging is minimized. Moreover, consumers prefer lightweight packaging, as it makes the product easier to handle, transport, and store. This combination of strength and weight reduction is achieved by carefully selecting materials that complement each other. For example, a durable outer layer made of PE can provide impact resistance, while the inner layers are optimized for barrier protection, resulting in a packaging solution that is both functional and efficient.

While multi-layer blow molding technology may require a higher initial investment in machinery and materials compared to single-layer molding, it offers significant cost benefits in the long run. Multi-layer technology allows for the use of less material in the production process, as the layers are designed to work in harmony, providing a high level of protection with fewer resources. The ability to produce bottles that offer greater protection extends the shelf life of products, reducing the likelihood of product spoilage and waste. Shaoxing Lizhi Plastic Products Co., Ltd. leverages multi-layer blow molding technology to provide cost-effective packaging solutions without sacrificing quality. By using this technology, the company can optimize material usage, reduce waste, and streamline production, all of which contribute to lower overall packaging costs. The durability and barrier properties of multi-layer bottles mean that products are less likely to be damaged during transit or storage, reducing the risk of loss and ensuring that the product reaches consumers in perfect condition.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français