Company

Shaoxing Lizhi Plastic Products Co., Ltd.

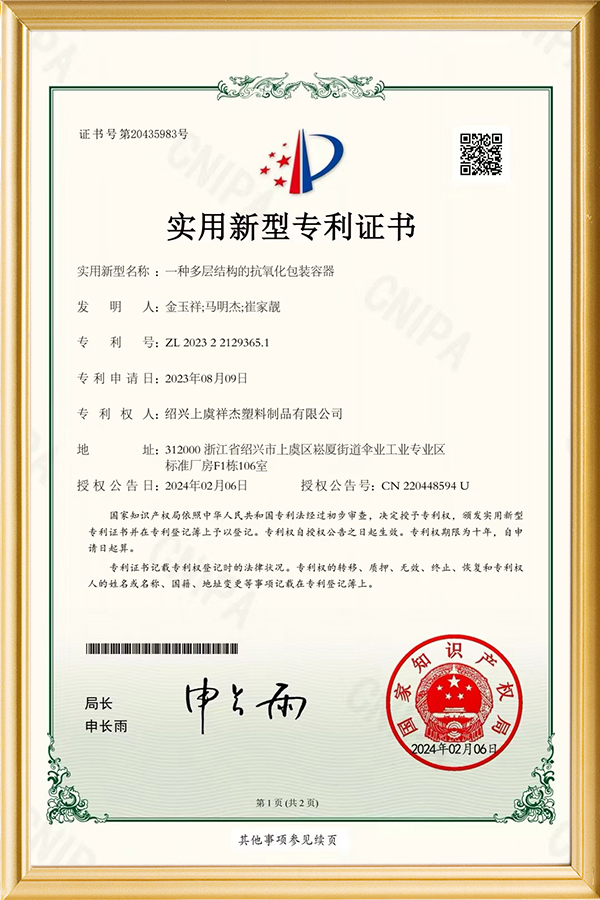

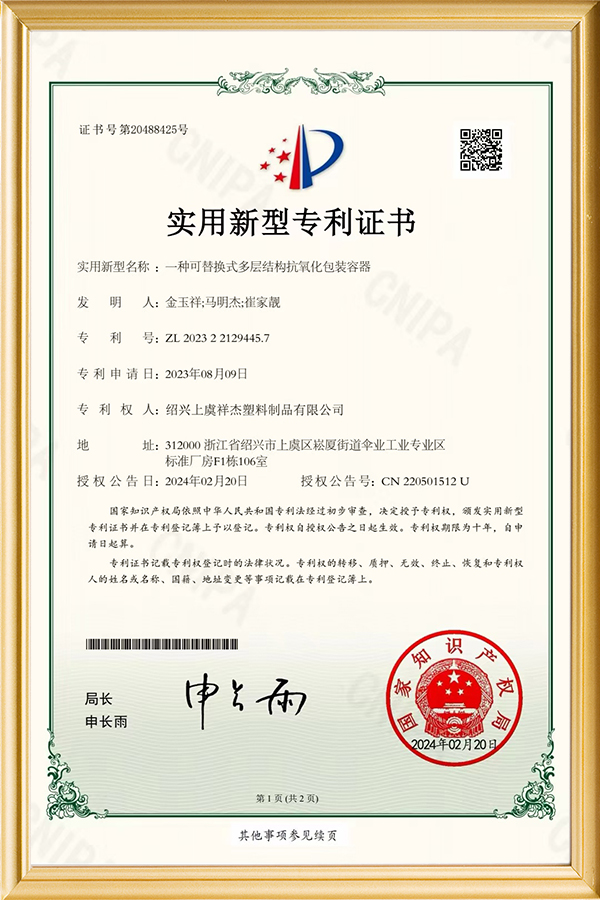

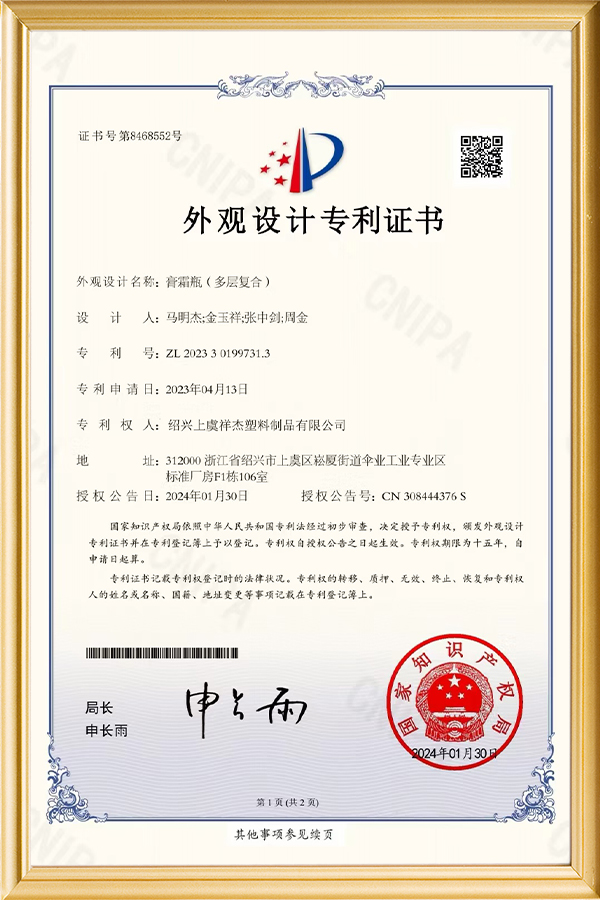

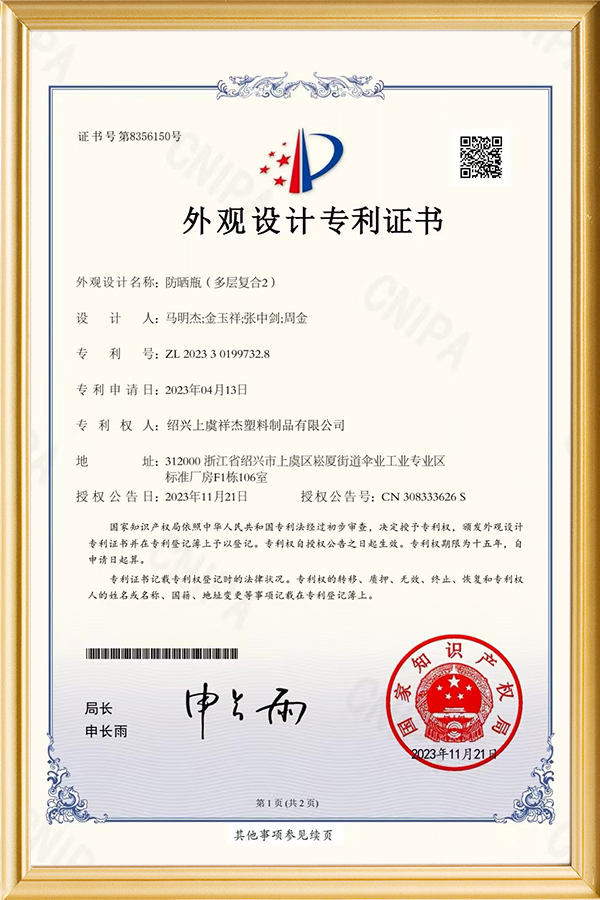

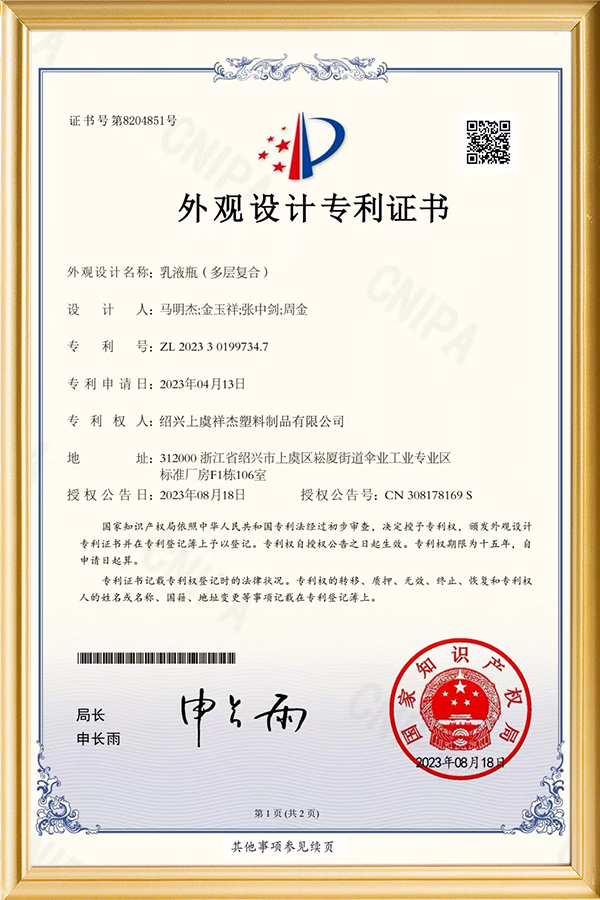

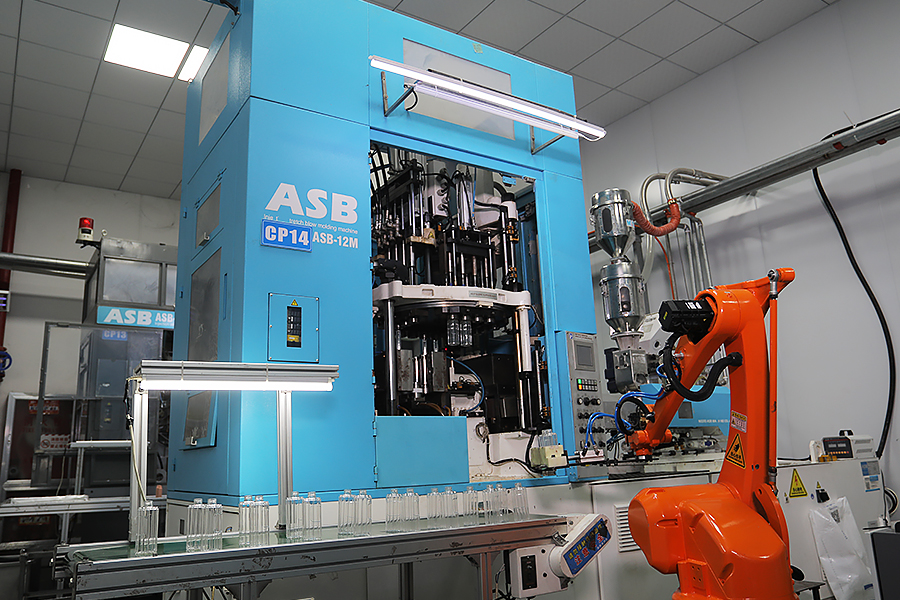

As a famous China Inner Bag Vacuum Bottle Manufacturers and Empty Inner Bag Vacuum Bottle Suppliers, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

How Does the Inner Bag Vacuum Bottle Improve Product Longevity?

Oxidation is one of the primary causes of product degradation, especially in cosmetics and skincare products that contain delicate ingredients like vitamins, antioxidants, and essential oils. Exposure to air accelerates the breakdown of these components, leading to the loss of color, fragrance, and efficacy. The Inner Bag Vacuum Bottle is designed with an inner bag that collapses as the product is dispensed, creating a vacuum seal that reduces the amount of air inside the container. This vacuum effectively slows down the oxidation process, preserving the integrity of sensitive ingredients and extending their shelf life. Without the constant exposure to air, these ingredients are less likely to degrade or lose their potency. The vacuum technology also helps eliminate the need for excessive preservatives, which are often added to compensate for the degradation caused by oxidation. As a result, consumers benefit from products that are fresher for longer, with fewer chemical additives. The advanced materials used in the production of these bottles further enhance this process. By using EVOH (ethylene vinyl alcohol), a material known for its exceptional oxygen barrier properties, the Inner Bag Vacuum Bottle offers an added layer of protection. EVOH prevents the ingress of oxygen, significantly reducing the chances of oxidation even further. This ensures that the product remains effective and retains its original properties throughout its shelf life. This type of packaging is particularly beneficial for high-end cosmetics that demand top-tier preservation, ensuring the brand’s reputation for quality and safety.

Cosmetic products are highly susceptible to contamination from external factors, including bacteria, dirt, and moisture, especially when used in environments like bathrooms where humidity levels are often high. Traditional packaging with exposed openings or pumps often requires frequent handling, which can introduce contaminants. In contrast, the Inner Bag Vacuum Bottle is engineered to minimize such risks by sealing the product inside an airtight environment. The vacuum seal and the collapsible inner bag work together to prevent contaminants from entering the bottle, ensuring that the product inside remains sterile and uncontaminated. This is particularly important for skincare products like serums and moisturizers, which often contain active ingredients that can be compromised by even minimal exposure to bacteria or dirt. The materials used in the Inner Bag Vacuum Bottle, such as PET, PE, and PETG, offer excellent resistance to moisture and UV light. Moisture is one of the main culprits behind product degradation, as it can cause the growth of mold or bacteria. The high-quality plastic materials used in the vacuum bottle are designed to block moisture and maintain the sterility of the contents, even in humid or damp conditions. In addition, the use of EVOH as a barrier material prevents light from penetrating the bottle, protecting light-sensitive ingredients from degradation caused by UV exposure. This makes the Inner Bag Vacuum Bottle an ideal packaging solution for products that need to stay fresh and uncontaminated over extended periods.

The longevity of a cosmetic product is greatly influenced by the quality of the materials used in its packaging. The Inner Bag Vacuum Bottle excels in this regard due to the use of advanced materials like EVOH, PET, PETG, and PP. Each of these materials is carefully selected for its specific properties that contribute to the bottle's overall performance. EVOH, for example, is highly resistant to oxygen, which prevents the product inside from being exposed to the elements that could cause it to spoil. This is especially important for products like anti-aging creams, sunscreens, and serums, which often contain ingredients sensitive to oxygen and UV light. The use of PETG and PET provides additional structural integrity to the bottle, ensuring that it remains durable and resistant to impact during handling, shipping, and storage. These materials are also known for their excellent barrier properties, further preventing the ingress of oxygen and moisture that could lead to the degradation of the product. PP (polypropylene) is often used for its durability and chemical resistance, providing an additional layer of protection to the contents inside. The combination of these materials creates a multi-layered defense system that protects the product, ensuring that it remains fresh and effective over time. Shaoxing Lizhi Plastic Products Co., Ltd. carefully selects these materials to meet the demands of modern consumers who prioritize both safety and sustainability. The company’s commitment to using high-quality, non-toxic materials ensures that the Inner Bag Vacuum Bottle is safe for both the product inside and the consumer, offering peace of mind along with premium packaging.

Another key advantage of the Inner Bag Vacuum Bottle is its precise dispensing system, which helps reduce wastage and ensures that the product inside is used efficiently. Traditional packaging systems, such as those with pumps or wide openings, can often dispense too much product at once, leading to waste. In contrast, the Inner Bag Vacuum Bottle uses a controlled dispensing mechanism that releases only the required amount of product, preventing excessive use. This controlled dispensing is particularly important for expensive or specialized cosmetic products, where consumers may wish to use the product sparingly. By dispensing the exact amount needed, the Inner Bag Vacuum Bottle ensures that the product is used efficiently, which directly contributes to its longevity. Additionally, this precise dispensing system also minimizes the number of times the bottle needs to be opened, reducing the risk of contamination each time the product is accessed. This is especially beneficial for high-end skincare products that are sensitive to exposure to air and contaminants. As a result, consumers can enjoy the full benefits of the product without the risk of it losing its effectiveness prematurely. The vacuum system and the design of the inner bag work in tandem to ensure that the bottle collapses uniformly as the product is dispensed, leaving no air pockets behind. This ensures that each use is clean and precise, preserving the product’s quality and preventing excess exposure to the environment.

In today’s world, consumers are not only concerned about the effectiveness of the products they purchase but also about the environmental impact of their packaging. Sustainability is an increasing priority for modern consumers, and the Inner Bag Vacuum Bottle is designed with this in mind. The materials used in its production, such as PET, PP, and EVOH, are all highly durable and recyclable, making the Inner Bag Vacuum Bottle a more sustainable option compared to traditional packaging. The eco-friendly design reduces the need for excessive preservatives, as the vacuum packaging prevents the product from deteriorating prematurely. This not only benefits the consumer by providing a fresher, safer product but also helps reduce the environmental footprint of the packaging process. Shaoxing Lizhi Plastic Products Co., Ltd. is committed to producing packaging that aligns with the growing consumer demand for environmentally responsible solutions. The company ensures that its Inner Bag Vacuum Bottles are made from recyclable materials, allowing consumers to dispose of them responsibly at the end of their lifecycle. The use of EVOH in the packaging contributes to the sustainability of the product by providing a high-performance barrier that ensures the product inside remains fresh without the need for chemical additives or preservatives. This results in cleaner, more natural formulations that appeal to health-conscious consumers who prioritize environmentally friendly and non-toxic products.

As a leading Inner Bag Vacuum Bottle Manufacturer and Inner Bag Vacuum Bottle Supplier, Shaoxing Lizhi Plastic Products Co., Ltd. is committed to maintaining the highest standards of quality control throughout the production process. The company’s investment in high-end Japanese imported machinery ensures that each Inner Bag Vacuum Bottle is manufactured with precision, consistency, and attention to detail. Each batch undergoes rigorous testing to ensure that the vacuum system is functioning correctly, the materials meet safety standards, and the bottle maintains its structural integrity. By adhering to strict quality control measures, Shaoxing Lizhi Plastic Products Co., Ltd. guarantees that every Inner Bag Vacuum Bottle not only delivers exceptional performance but also offers durability and reliability. The company's focus on quality ensures that the packaging effectively preserves the product inside, enhancing the longevity of both the product and the packaging itself.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français