Company

Shaoxing Lizhi Plastic Products Co., Ltd.

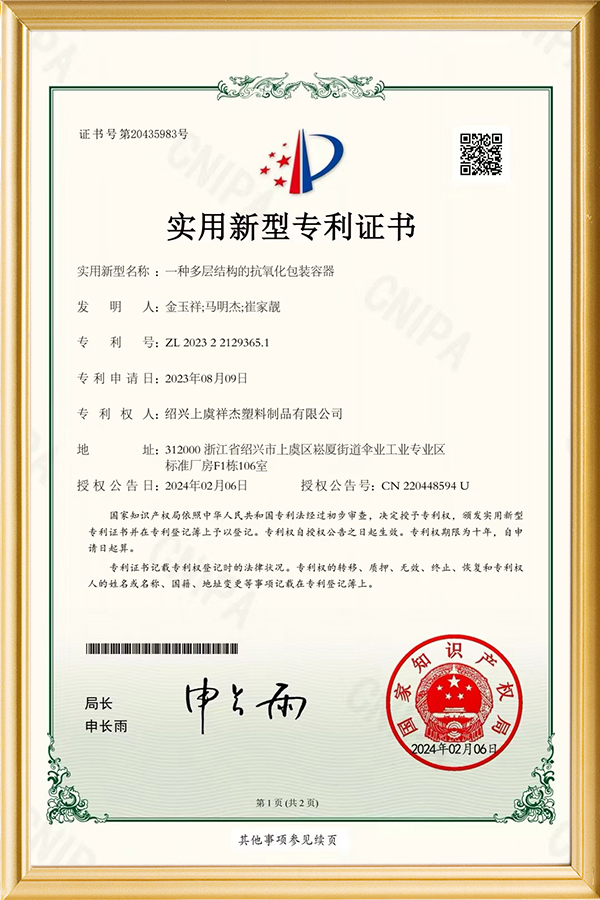

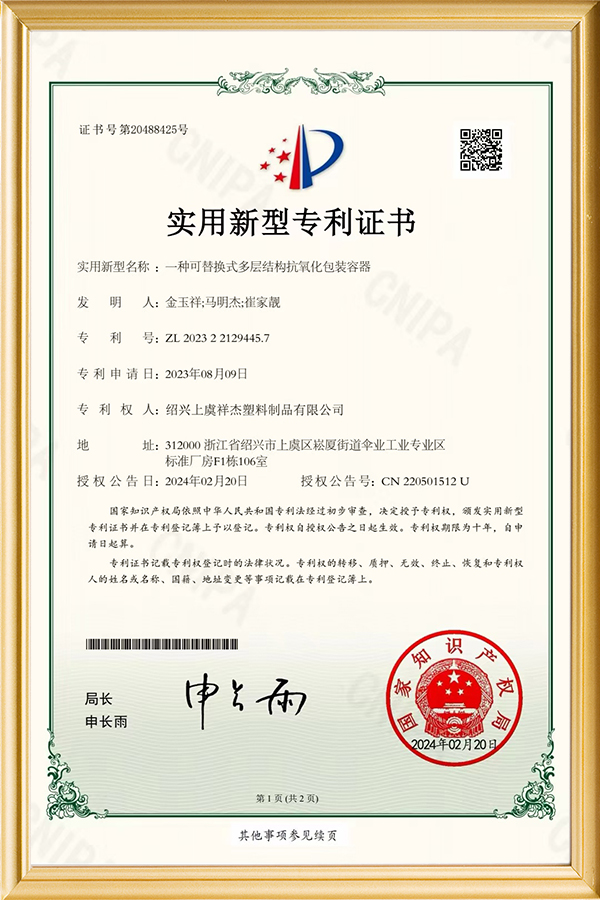

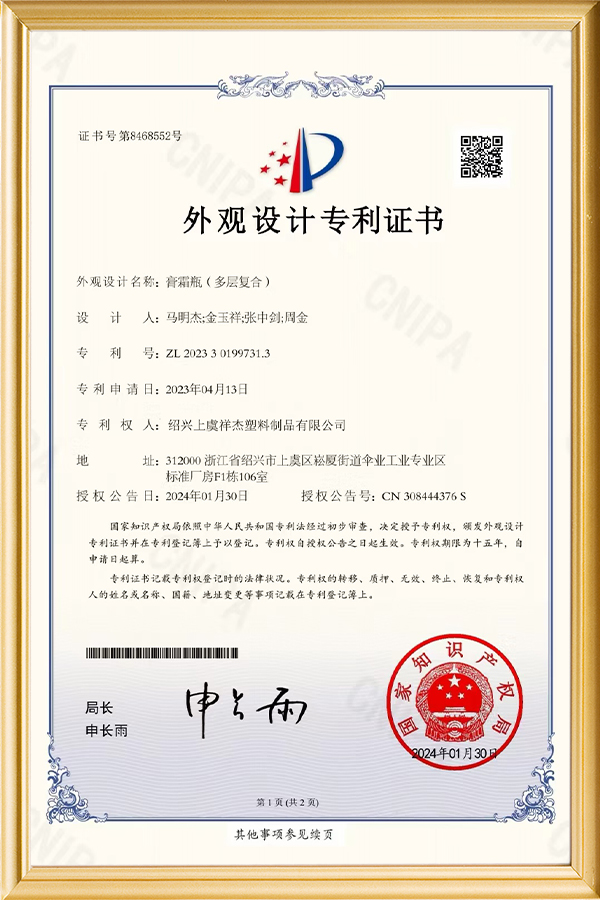

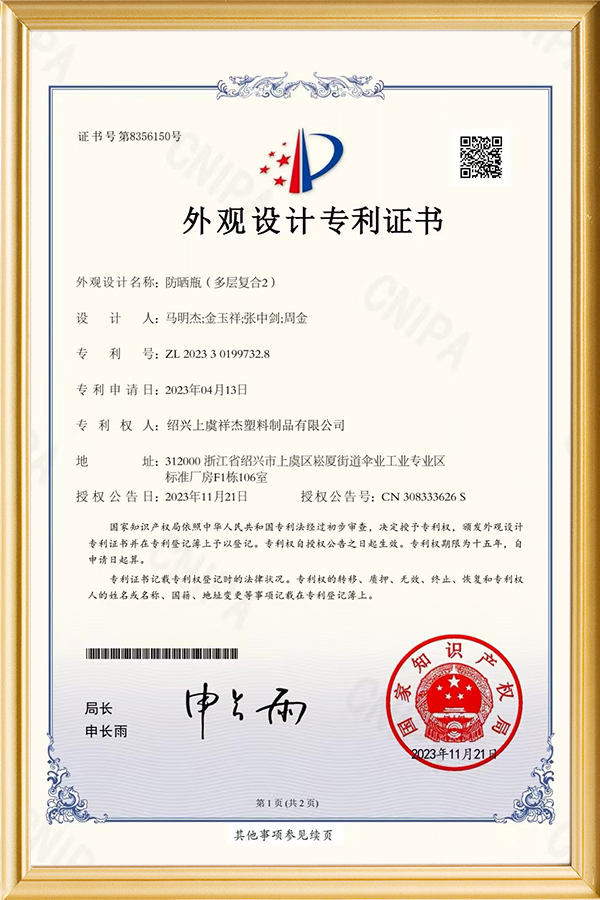

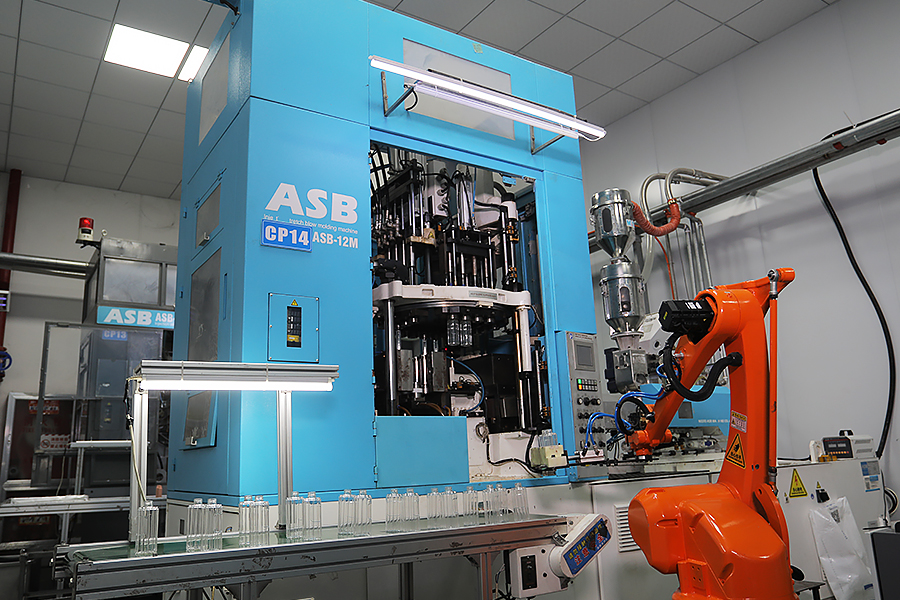

As a famous China Multi-Layer Sunscreen Bottle Manufacturers and EVOH Sunscreen Bottle Suppliers, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

How Does the Multi-layer Technology Enhance the Performance of the EVOH Sunscreen Bottle?

One of the most significant advantages of multi-layer technology is its ability to provide superior protection against external elements, such as oxygen, moisture, UV rays, and light, which can degrade the sunscreen formula inside the bottle. EVOH is particularly well-suited for this role due to its exceptional oxygen barrier properties. Oxygen, when allowed to permeate the packaging, can react with the active ingredients in sunscreens, leading to the breakdown of vitamins, antioxidants, and sun-blocking agents, ultimately diminishing the product's effectiveness over time. In addition to EVOH's protective role, the other layers, such as PET (Polyethylene Terephthalate) or PE (Polyethylene), further strengthen the physical barrier of the bottle, offering protection against moisture. This moisture barrier ensures that the sunscreen formula remains stable and does not lose its consistency due to environmental factors, such as humidity, which could otherwise cause separation of ingredients or promote microbial growth. The multi-layer design enables the packaging to withstand prolonged exposure to UV light, which is essential for sunscreen products that are directly exposed to sunlight in retail environments or during consumer use. UV-sensitive ingredients in sunscreens can lose their effectiveness when exposed to sunlight, but the EVOH multi-layer bottle helps prevent this by significantly reducing UV penetration.

The multi-layer design ensures that the sunscreen maintains its freshness and potency for an extended period. Sunscreen products rely heavily on the stability of their active ingredients to deliver the promised UV protection. When these ingredients are exposed to oxygen and light, they can undergo chemical changes that reduce their effectiveness. By incorporating layers such as EVOH, the packaging offers an impenetrable barrier to oxygen, preventing the oxidation process that could degrade the sunscreen's protective capabilities. The layers of material used in multi-layer blow molding technology also help in maintaining the sunscreen’s fragrance, preventing it from dissipating or becoming tainted due to external exposure. EVOH prevents the permeation of volatile organic compounds (VOCs) that could potentially interact with the product inside, thus ensuring that the sunscreen maintains its original formula throughout its shelf life. This extended shelf life is a critical factor for consumers who demand long-lasting protection and high-quality packaging.

In addition to protecting the sunscreen formula from external degradation, the multi-layer technology also contributes to the mechanical strength and durability of the bottle itself. The construction of the bottle using various materials, such as PP (Polypropylene), PET, and PE, imparts strength and flexibility that single-layer bottles simply cannot offer. The outer layers of the bottle, often made from PP or PET, provide added structural integrity, ensuring that the bottle can withstand the rigors of transportation, handling, and storage. Whether the sunscreen is shipped from manufacturing plants to retail stores or handled by consumers in daily use, the multi-layer construction ensures that the packaging remains intact and functional. Multi-layer bottles are less prone to cracking or breaking under stress, which is particularly important for sunscreen products, as consumers often carry them in bags or use them outdoors, where they may encounter physical stress or drops. The combination of materials within a multi-layer design ensures that the bottle is tough yet lightweight, offering a premium experience without sacrificing functionality.

The use of multi-layer technology also allows for customization of the bottle's properties, which can be crucial for brands that want to differentiate themselves in the competitive cosmetics market. The various layers used in the multi-layer process can be tailored to meet specific brand aesthetics, ergonomics, and functional needs. For instance, the outer layer of the EVOH Multi-layer Sunscreen Bottle may feature advanced printing or coating technologies, which enable vivid branding, custom colors, and premium finishes such as matte or glossy effects. This offers brands the opportunity to create a unique look that aligns with their brand identity while maintaining the necessary protection inside. Brands can incorporate additional functional layers, such as easy-to-use dispensing systems, flip-top caps, or pump dispensers, ensuring convenience for consumers. Customization also extends to the shape and design of the bottle, which can be optimized for ease of handling and portability, factors that are important to consumers using sunscreen on-the-go.

As sustainability becomes an increasing priority for both consumers and brands, multi-layer packaging offers a range of environmental benefits, making it an attractive choice for companies focused on reducing their carbon footprint. Shaoxing Lizhi Plastic Products Co., Ltd., a leader in multi-layer blow molding, is committed to sustainability by using eco-friendly materials and incorporating environmentally responsible practices into the production process. By utilizing EVOH in combination with PET and PE, the multi-layer bottles can be made recyclable, providing consumers with the opportunity to dispose of the packaging responsibly. While EVOH itself is not easily recyclable, the bottles can still be processed in specialized recycling streams, reducing the amount of waste generated by traditional single-layer plastic packaging. The EVOH Multi-layer Sunscreen Bottle reduces the need for preservatives or chemical additives in the sunscreen formula due to its excellent barrier properties. This reduction in the use of additives can contribute to the overall sustainability of the product, as consumers demand packaging that aligns with their eco-conscious values.

While multi-layer technology may initially appear more costly to implement compared to single-layer alternatives, it offers long-term cost-efficiency by optimizing the performance of the product. The ability to incorporate different materials at various layers allows for the customization of the packaging to meet specific functional and aesthetic requirements without over-engineering the product. This means that brands can achieve high-end performance and protection for their sunscreens while minimizing the use of costly raw materials, such as pure EVOH, and relying on more economical materials in the outer layers. The result is a premium product that offers outstanding performance, durability, and aesthetic appeal while maintaining a reasonable cost structure for both manufacturers and consumers. Multi-layer bottles can be lighter and more efficient in terms of material usage compared to single-layer alternatives, reducing the overall carbon footprint of the packaging and lowering transportation costs due to their lower weight.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français