Company

Shaoxing Lizhi Plastic Products Co., Ltd.

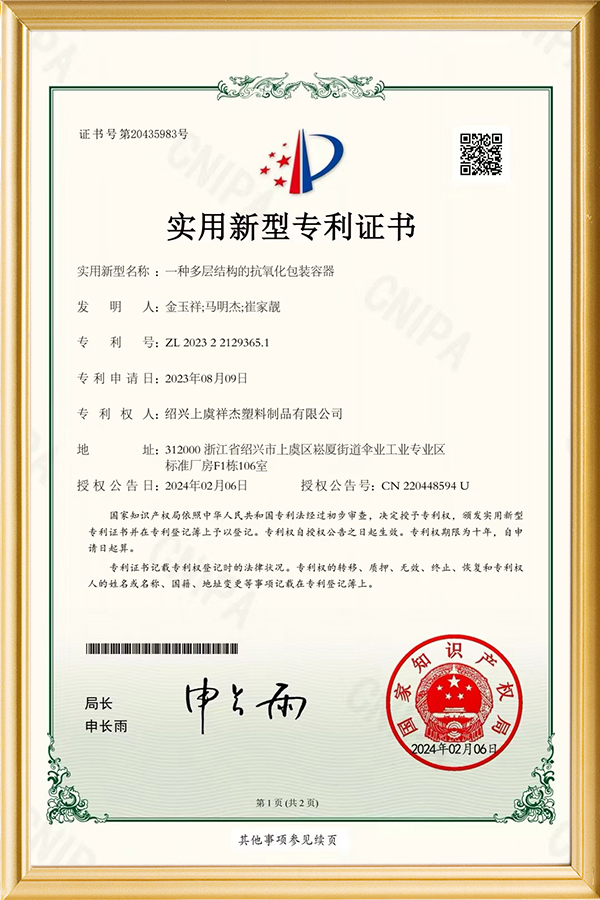

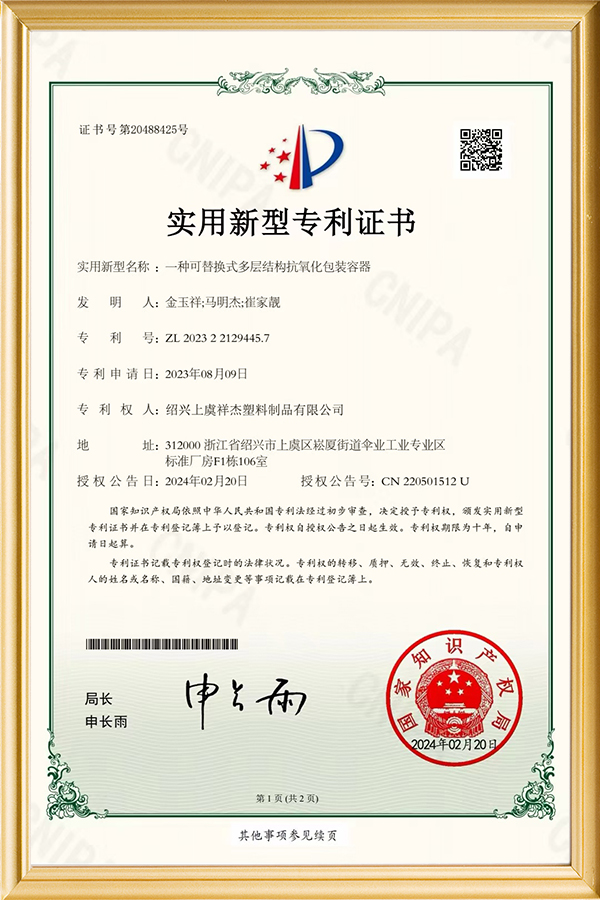

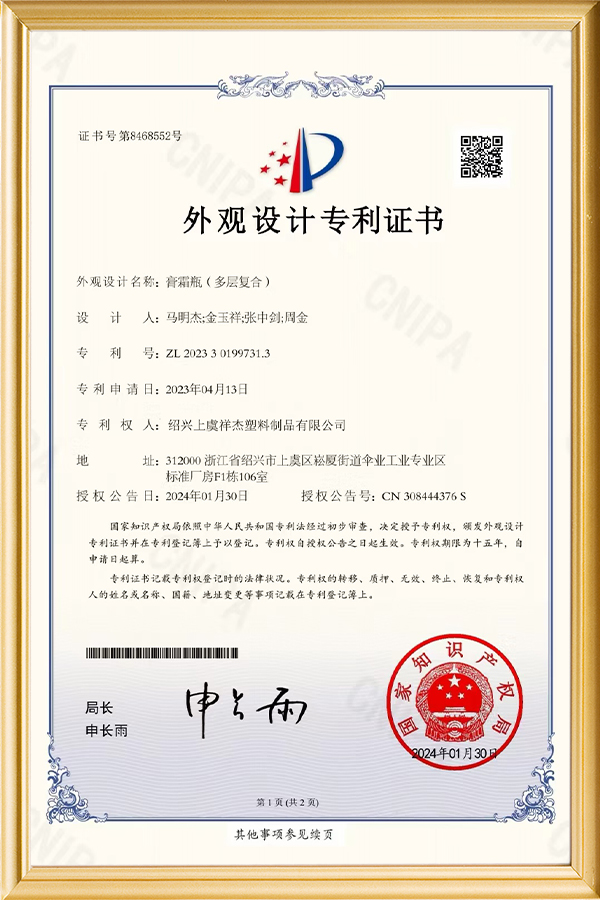

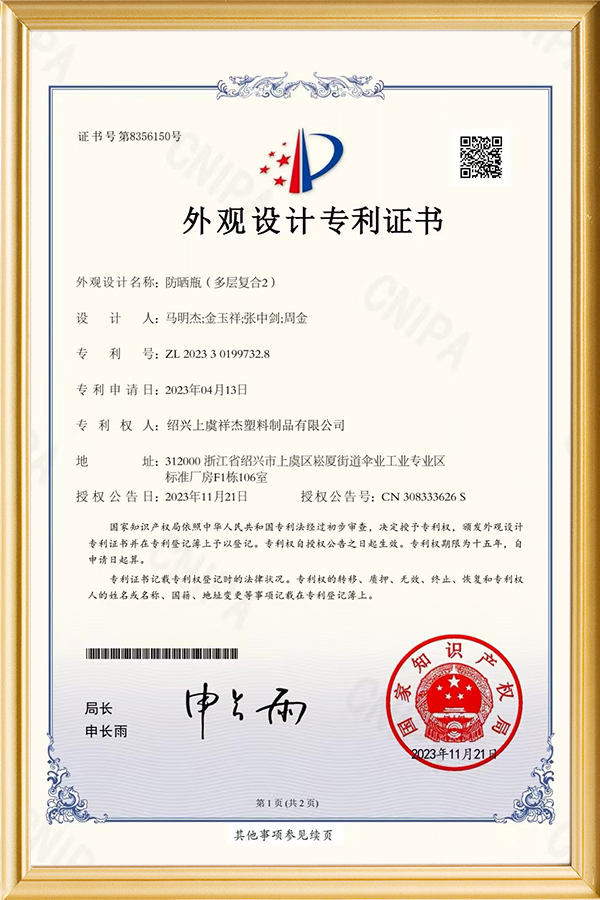

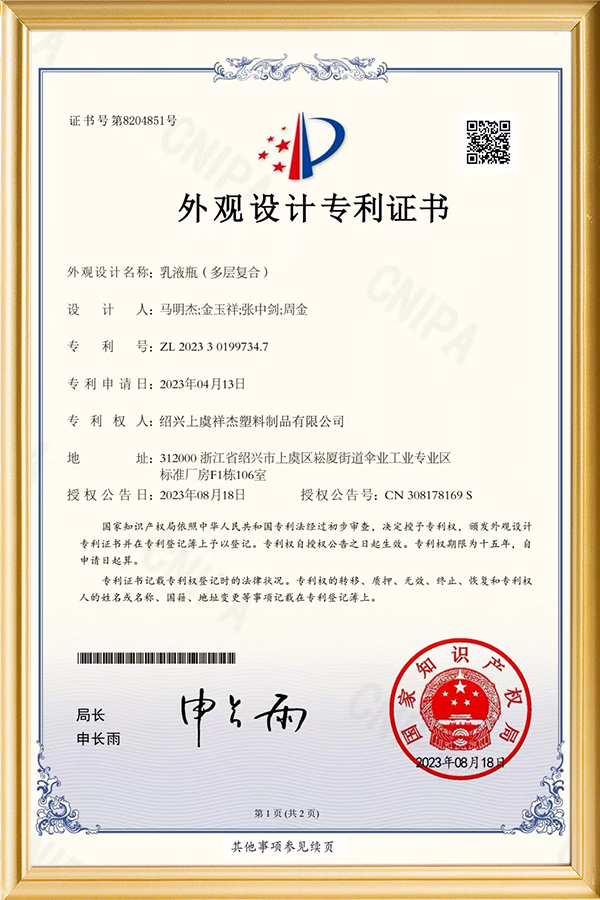

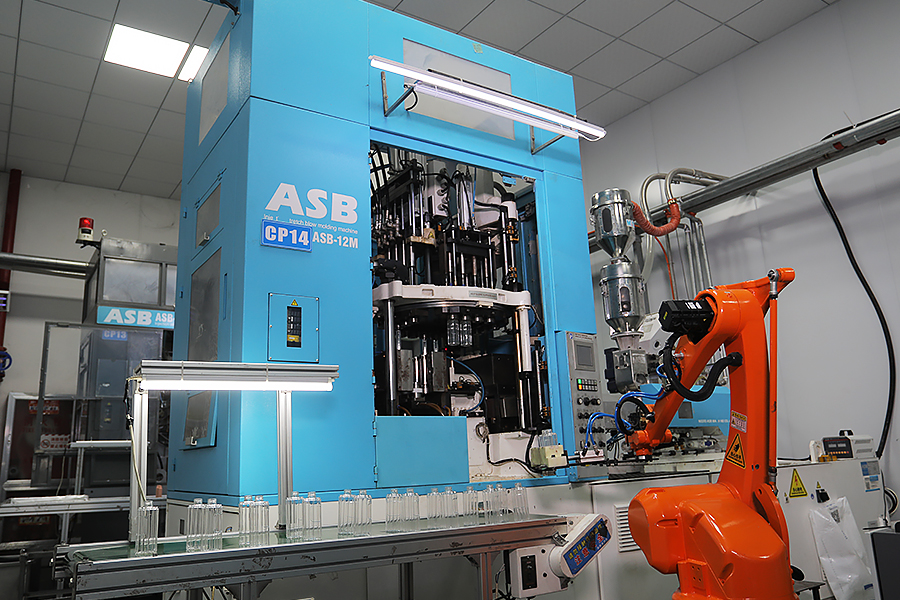

As a famous China Single-layer Sunscreen Bottle Manufacturers and Empty Single-layer Sunscreen Bottle Suppliers, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

How Does the Blow Molding Process Enhance the Quality of Single-layer Sunscreen Bottles?

Blow molding provides a high level of precision in manufacturing, which is essential for ensuring that each Single-layer Sunscreen Bottle is uniform in size and quality. The advanced machinery used by Shaoxing Lizhi Plastic Products Co., Ltd., including Japanese-imported blow molding equipment, enables precise control over the material distribution and mold design. The manufacturing process begins with a molten parison, which is inflated to form the bottle’s shape. This step ensures that the material thickness is even, which is crucial for the bottle’s strength and durability. With blow molding, the consistency in wall thickness is achieved, preventing any areas of weakness that could lead to cracks or leaks, common problems with other less advanced molding methods. This precise control also ensures that the bottle is not only strong but also lightweight, which makes it more cost-effective for production without compromising on its performance. The end result is a Single-layer Sunscreen Bottle that is functional, durable, and meets the cosmetic packaging industry's high-quality standards.

One of the key benefits of the blow molding process is the enhanced strength and durability it imparts to the Single-layer Sunscreen Bottle. Blow molding uses high-quality materials such as PP (Polypropylene), PE (Polyethylene), PET (Polyethylene Terephthalate), and EVOH, which are known for their resilience. These materials are perfectly suited for cosmetic packaging, where maintaining product safety and integrity is paramount. The design flexibility inherent in blow molding allows these materials to be molded into thin yet robust walls, meaning the bottle can withstand everyday wear and tear, including rough handling during shipping and storage. This durability is particularly important for Single-layer Sunscreen Bottles, which are often used in environments that require the bottle to resist impact, pressure, and potential cracking. For instance, when bottles are subjected to pressure from being stored in tight spaces or being dropped, a blow-molded bottle is far less likely to break than other plastic alternatives. These materials are resistant to UV rays and temperature fluctuations, which can affect the sunscreen inside. Shaoxing Lizhi Plastic Products Co., Ltd. ensures that the final product is able to maintain its physical integrity and protect the sunscreen from degrading due to external factors.

Blow molding is not just a technique that ensures the product’s strength and durability; it is also one of the most cost-efficient methods for producing Single-layer Sunscreen Bottles. Unlike injection molding, which requires complex molds and more material waste, blow molding uses a relatively simple process that minimizes material wastage. The molten plastic is extruded into a parison, which is then inflated to take the shape of the mold. This process allows for an even distribution of the material, ensuring that the bottles are thin yet strong. Shaoxing Lizhi Plastic Products Co., Ltd. takes full advantage of this material optimization by using just the right amount of plastic required for each bottle, thus reducing both production costs and environmental impact. The ability to use minimal materials while still producing a durable and high-quality bottle makes blow molding particularly advantageous for Single-layer Sunscreen Bottles, where affordability is key without sacrificing quality. The result is a competitive edge in the marketplace, offering both consumers and manufacturers a product that is cost-effective to produce and buy while maintaining its protective and aesthetic qualities.

The aesthetic appeal of a Single-layer Sunscreen Bottle plays a critical role in how the product is perceived by consumers. Blow molding offers considerable flexibility when it comes to design. With this method, Shaoxing Lizhi Plastic Products Co., Ltd. can create bottles that are not only functional but also visually appealing. The precise molding technology allows for smooth surfaces, sharp contours, and clean lines that give the bottle a sleek, high-end appearance. Furthermore, blow molding enables customization options such as ergonomic shapes that fit comfortably in the hand, textured grips, and even embossing of logos or brand names. The ability to design such features at a high level of detail gives manufacturers the opportunity to create a Single-layer Sunscreen Bottle that reflects the branding and identity of the cosmetic product. Consumers often associate the packaging design with the quality of the product, and having a bottle that is not only functional but also aesthetically pleasing can greatly enhance the consumer’s experience. Shaoxing Lizhi Plastic Products Co., Ltd.’s use of blow molding technology ensures that every bottle stands out on the shelf, encouraging purchases and enhancing brand recognition.

In the production of Single-layer Sunscreen Bottles, compatibility with filling systems is essential for efficient and seamless production. Blow molding plays a critical role in ensuring that the design and structure of the bottle accommodate various dispensing and filling methods. Whether it is a screw cap, a flip-top lid, or a pump dispenser, blow molding can produce bottles with precisely shaped necks that are compatible with these closure systems. This is particularly important for Single-layer Sunscreen Bottles, which are typically filled with sunscreen lotions or creams. The precision achieved through blow molding ensures that the neck opening is consistent, reducing the risk of leakage or improper sealing. Additionally, the uniformity of the molded structure allows for smooth integration with automated filling lines, which is crucial for scaling up production. At Shaoxing Lizhi Plastic Products Co., Ltd., blow molding is used to create bottles that perform well with high-speed filling operations, reducing bottlenecks in the manufacturing process and ensuring that the packaging is both efficient and cost-effective.

Another key advantage of the blow molding process is its ability to enhance the barrier properties of the packaging material. The high-quality plastic materials used in blow molding, such as EVOH (Ethylene Vinyl Alcohol), provide superior protection against oxygen, moisture, and UV light. Sunscreen products are sensitive to environmental factors such as light and air, which can break down the active ingredients over time. By incorporating materials like EVOH into the blow-molded bottle design, Shaoxing Lizhi Plastic Products Co., Ltd. ensures that the Single-layer Sunscreen Bottle protects the sunscreen from UV rays and prevents the degradation of the product inside. This feature helps the sunscreen retain its quality throughout its shelf life, offering customers a product that is both effective and safe to use. The enhanced barrier properties help to prevent contamination, ensuring that the contents remain pure and free from external pollutants.

In today’s market, consumers are increasingly concerned with sustainability and the environmental impact of the products they use. Blow molding, as a manufacturing process, is inherently more sustainable than many other molding techniques. The material waste generated during the blow molding process is minimal, as it involves using only the necessary amount of plastic. The plastic materials used in blow molding, such as PET and PP, are highly recyclable. This makes Single-layer Sunscreen Bottles produced via blow molding an environmentally friendly option for packaging sunscreen products. Shaoxing Lizhi Plastic Products Co., Ltd.’s commitment to sustainability means that their bottles are not only cost-effective and durable but also contribute to reducing the overall environmental footprint of the cosmetics packaging industry. The ability to recycle the packaging after use ensures that the Single-layer Sunscreen Bottles can be reused in other applications, promoting a circular economy.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français