Company

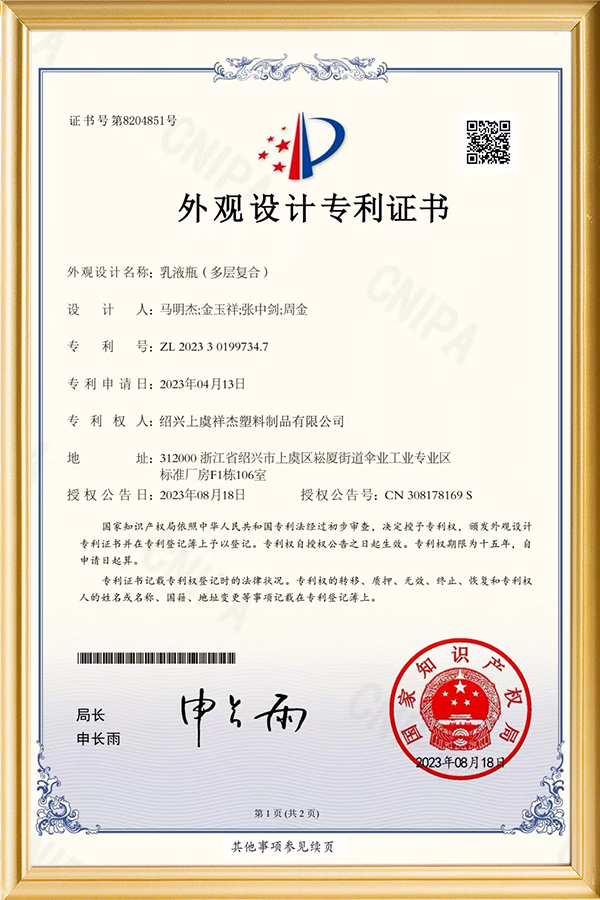

Shaoxing Lizhi Plastic Products Co., Ltd.

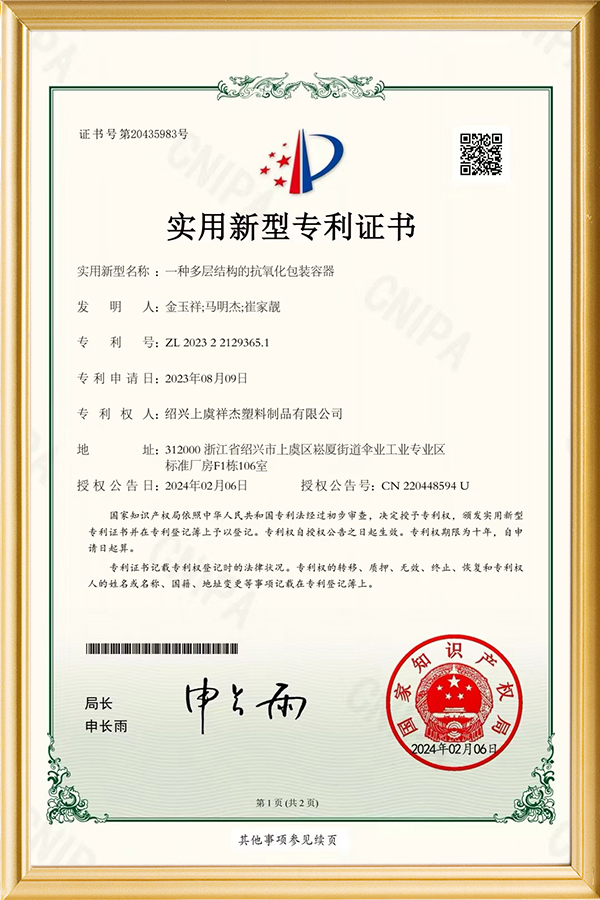

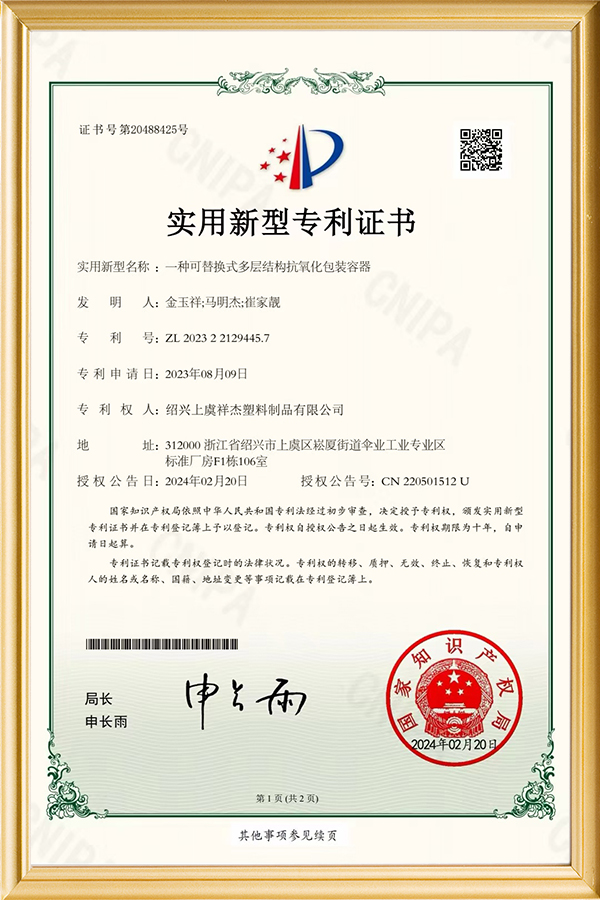

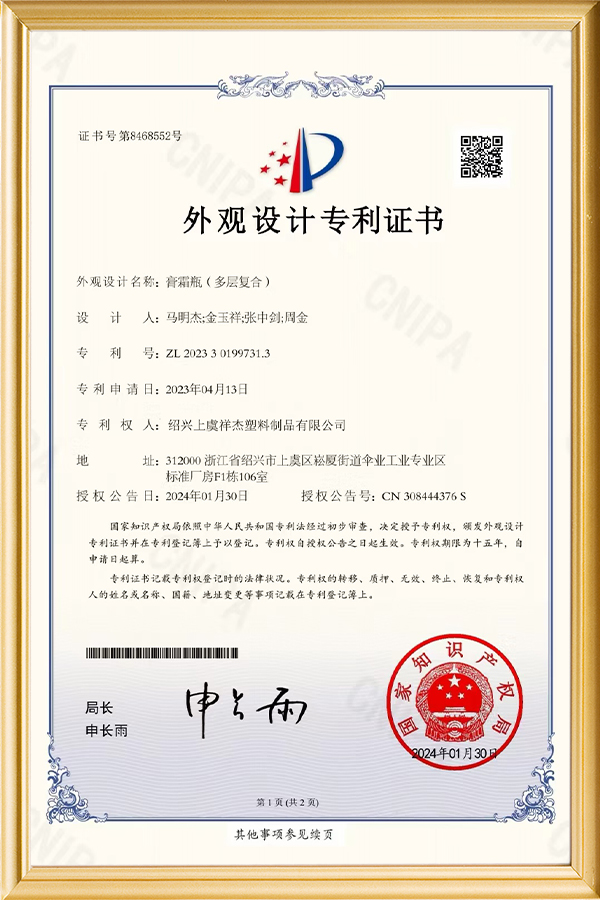

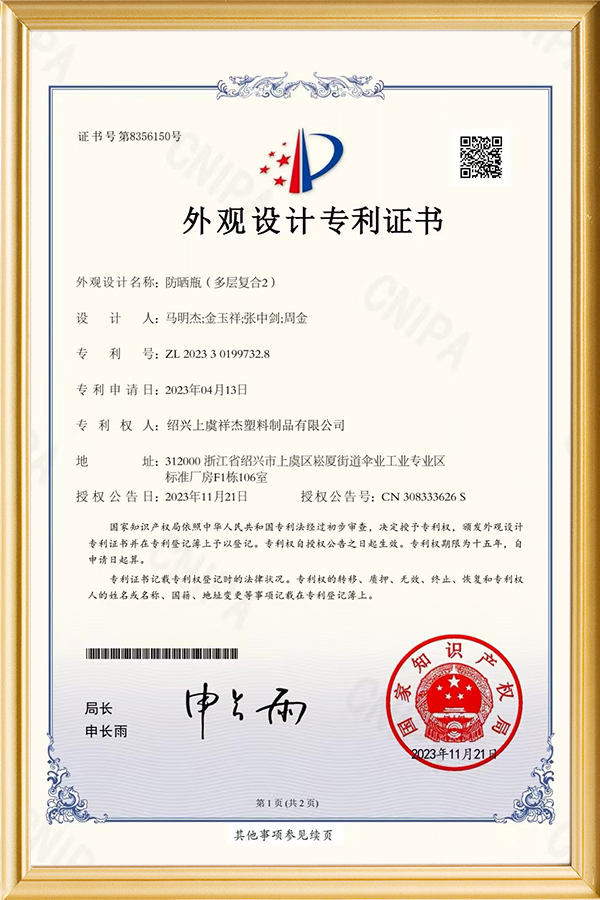

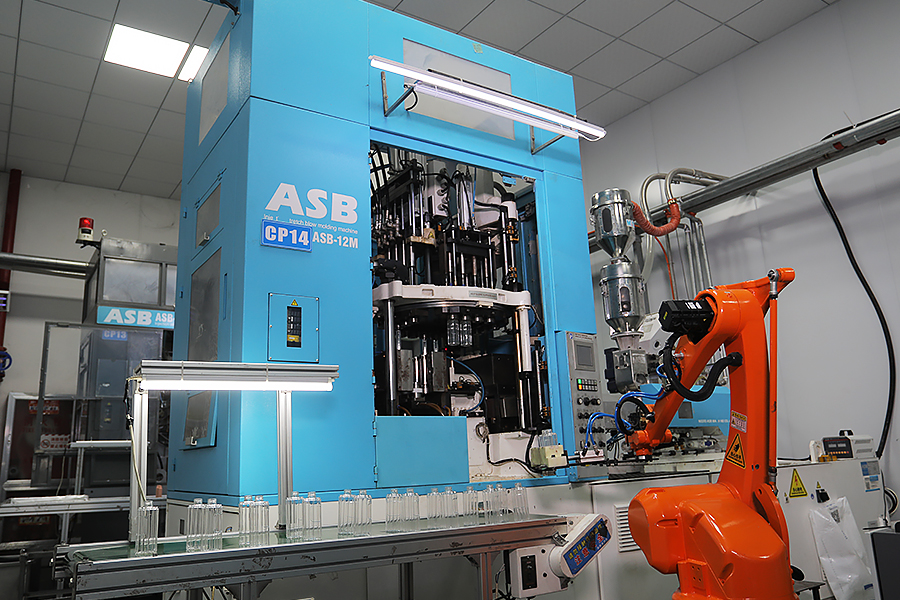

As a famous China Thick Wall Bottle Series Manufacturers and Empty Thick Wall Bottle Series Factory, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

The Manufacturing Process of Thick Wall Bottles

The process of manufacturing thick wall bottles begins with the selection and preparation of raw materials, which is a crucial step in ensuring the final product's durability, flexibility, and safety. Shaoxing Lizhi Plastic Products Co., Ltd. uses premium materials like Polypropylene (PP), Polyethylene (PE), Polyethylene Terephthalate (PET), Polyethylene Terephthalate Glycol (PETG), and Ethylene Vinyl Alcohol (EVOH). These materials are selected based on their unique properties that make them suitable for different types of packaging. PP is chosen for its strength, resistance to heat, and ability to maintain its integrity under pressure. PE offers flexibility and moisture resistance, which are important for products that require a high degree of elasticity without sacrificing strength. PET is known for its excellent clarity, making it a top choice for premium cosmetic packaging, as it not only protects the product but also showcases it attractively. PETG, a more flexible and transparent version of PET, is used when both durability and aesthetic appeal are needed. EVOH is selected for its exceptional barrier properties, preventing oxygen, moisture, and light from compromising the product's integrity. These materials are preheated or dried to ensure they are in ideal condition for molding, preventing issues such as moisture-related defects during production. The material selection and preparation stage is essential as it determines the bottle’s overall performance and suitability for specific applications.

The key to manufacturing thick wall bottles lies in the blow molding process, which at Shaoxing Lizhi Plastic Products Co., Ltd. is performed using advanced single-layer and multi-layer blow molding techniques. Blow molding is a process where a heated plastic parison is inflated to form the desired bottle shape inside a mold. The blow molding process ensures that the bottles maintain consistent wall thickness, which is essential for the durability and strength of thick wall bottles. Extrusion blow molding is typically used, where molten plastic is extruded into a hollow tube or parison, which is then inflated to fit the mold. This allows for uniform wall thickness and consistent design. For thicker walls, additional material is extruded to ensure that the walls do not become too thin, thus preventing weak points that could lead to cracking or breaking. In addition to extrusion blow molding, injection blow molding is another technique used for thicker bottles, especially when precision and clarity are required. In this method, a preform is injection molded into a specific shape and then transferred to a blow mold where it is inflated to the final size. This method offers greater control over the thickness and quality of the walls, especially for high-end cosmetic packaging that requires both aesthetic appeal and functionality. Multi-layer blow molding is employed when additional protection is necessary, such as incorporating EVOH to enhance oxygen barrier properties. This technology allows for creating multi-layer bottles, ensuring that different layers serve distinct functions, such as providing strength, protection, or resistance to environmental factors. The blow molding process used by Shaoxing Lizhi Plastic Products Co., Ltd. is crucial in ensuring that the thick wall bottles have the desired durability, clarity, and structural integrity, making them ideal for products that require both high-performance packaging and visual appeal.

Once the blow molding process is completed, the next step is the mold design, which plays a critical role in determining the final appearance and functionality of the thick wall bottles. At Shaoxing Lizhi Plastic Products Co., Ltd., experienced mold designers work closely with clients to create custom molds that meet their specific design and branding needs. The molds are created using advanced CNC machining techniques, ensuring that every detail, from the overall shape to small branding elements, is precisely crafted. Customization is a key advantage in bottle production, allowing clients to differentiate their products in the market. Custom molds can incorporate intricate features such as embossed logos, textured finishes, and unique bottle shapes. The company’s design team ensures that the molds are optimized for efficient material flow, preventing defects like air pockets or uneven wall thickness. Proper mold design ensures that the material is distributed evenly during the blow molding process, which results in uniform bottle walls and a consistent finished product. Shaoxing Lizhi offers a range of design possibilities, from sleek, simple bottle shapes to more intricate, decorative designs. Custom molds allow for a high degree of flexibility in packaging, ensuring that each bottle aligns with the brand’s identity and meets the functional requirements for different applications.

After the molding process, the next crucial step is cooling and solidifying the thick wall bottles. Cooling is necessary to ensure that the molded plastic retains its shape and strength once removed from the mold. At Shaoxing Lizhi Plastic Products Co., Ltd., the cooling process is carefully controlled using both air and water cooling systems to ensure uniform cooling across the entire bottle. As the bottles cool, they solidify into their final shape. This is a delicate process, as the cooling rate must be carefully managed to avoid warping or distortion of the bottle shape. Thicker walls require longer cooling times to ensure that the material fully solidifies, preventing shrinkage or weakness in the bottle. Cooling time is determined by several factors, including the material used, the thickness of the walls, and the shape of the bottle. For thicker bottles, a slow and even cooling process is essential to ensure that the final product is free from defects like warping or cracking. Precise temperature control ensures that the cooling process occurs uniformly throughout the bottle. If the cooling is uneven, it can lead to inconsistencies in the bottle structure, which could impact its strength and appearance. Therefore, Shaoxing Lizhi Plastic Products Co., Ltd. utilizes advanced cooling systems to guarantee that the thick wall bottles maintain their strength and appearance while preventing any potential defects caused by improper cooling.

Quality control is an integral part of the thick wall bottle manufacturing process, ensuring that each bottle produced meets the highest standards of safety, performance, and aesthetics. At Shaoxing Lizhi Plastic Products Co., Ltd., strict quality control measures are implemented at every stage of production. This includes testing for wall thickness uniformity, ensuring that the walls of each bottle are consistent and free from weak spots. Any variations in thickness could lead to a compromised structure, making the bottle more prone to breakage or deformation. Each batch of bottles undergoes impact resistance testing to ensure that they can withstand drops or external forces without cracking. This is particularly important for bottles used in cosmetics, where the packaging must protect delicate products during shipping and handling. Leakage testing is also performed to ensure that bottles are properly sealed and do not leak, especially for multi-layer bottles. This is vital for maintaining product integrity and preventing contamination. Bottles are also subjected to visual inspection to check for any surface defects, such as scratches, dents, or discoloration. These tests ensure that every thick wall bottle produced by Shaoxing Lizhi Plastic Products Co., Ltd. not only meets functional requirements but also maintains a high level of aesthetic quality that appeals to consumers.

After passing the quality control tests, the bottles are ready for decoration and labeling, which is a key step in enhancing their visual appeal and ensuring brand recognition. Shaoxing Lizhi Plastic Products Co., Ltd. offers a variety of decoration techniques to customize the appearance of the thick wall bottles, allowing clients to align their packaging with brand identity and aesthetic preferences. Silkscreen printing and heat transfer printing are commonly used to apply logos, product names, and other branding elements to the bottle surface. These methods ensure that the printed information remains intact, even with regular use or exposure to various environmental conditions. For premium cosmetic products, embossing and debossing techniques can be employed to create a tactile experience that adds a high-end feel to the packaging. Hot stamping is another method used for adding metallic finishes to the bottles, giving them an extra touch of elegance and luxury. Glossy finishes can also be applied to enhance the visual appeal and give the bottle a shiny, polished look. The decoration process is crucial in creating a strong visual impact on store shelves, and Shaoxing Lizhi Plastic Products Co., Ltd. ensures that each bottle is finished to perfection with high-quality printing and decoration techniques.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français