Company

Shaoxing Lizhi Plastic Products Co., Ltd.

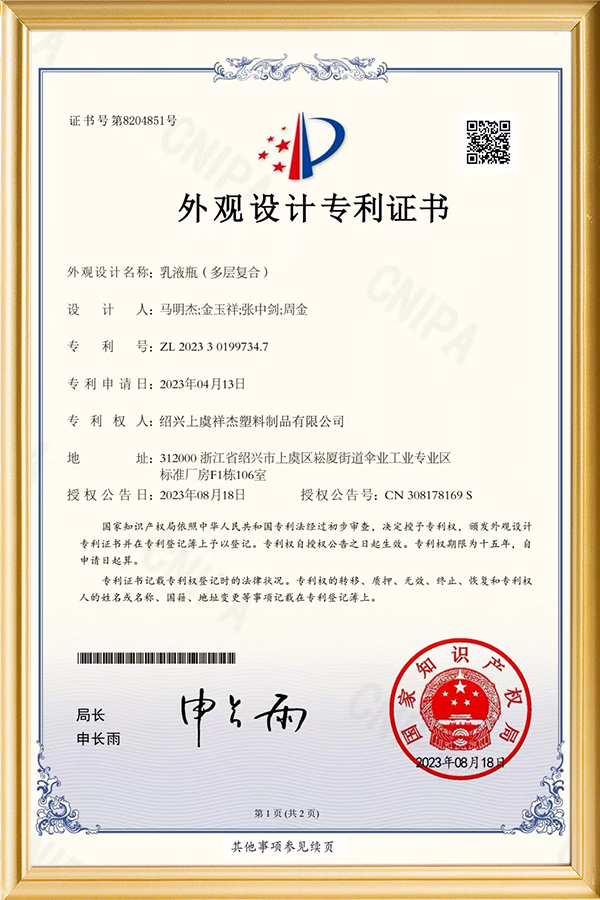

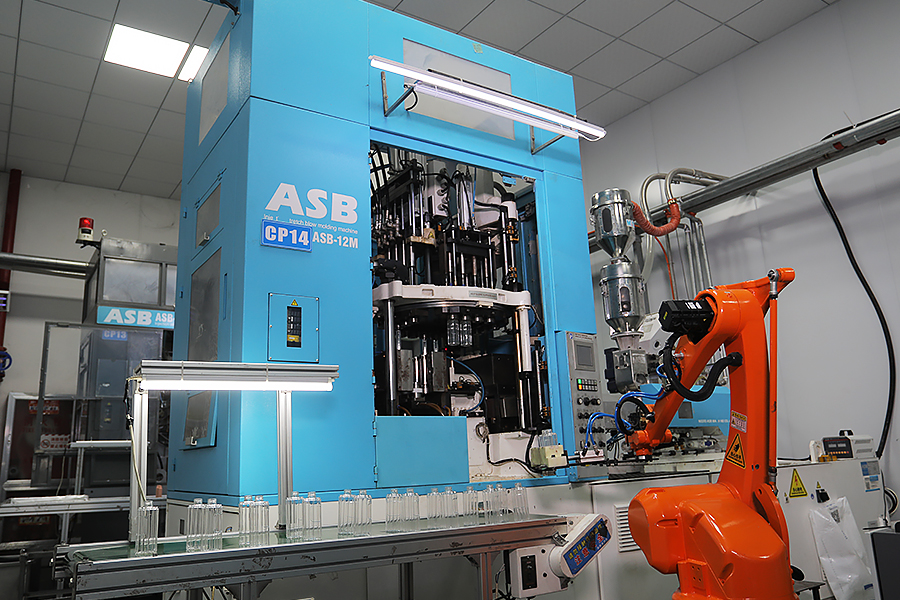

As a famous China Thick Wall PETG bottle Manufacturers and Thick Wall PET Bottle Suppliers, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

How Do Thick Wall PET Bottles Provide Enhanced Protection for Contents?

One of the most notable advantages of Thick Wall PET Bottles is their enhanced physical strength. The thicker walls make these bottles far more resistant to external pressures, including impacts, drops, and mishandling. For instance, in the cosmetics industry, where products are often transported and stored in varying conditions, a robust bottle design ensures that the product inside remains secure, even during rough handling. Shaoxing Lizhi Plastic Products Co., Ltd., a leading manufacturer of Thick Wall PET Bottles, ensures that the thickness of the PET material not only provides strength but also enhances the bottle's ability to resist deformation. This is particularly important for products that need to maintain their form and packaging integrity throughout distribution and storage. The extra material in the walls prevents cracks, dents, and other forms of physical damage that could otherwise compromise the packaging or the product inside. The thick walls make these bottles less prone to bursting or leakage, which is a critical factor when dealing with products that need to be sealed tightly to avoid contamination or spoilage. This enhanced durability helps maintain the quality of the product and ensures that the packaging remains intact for a longer period.

Thick Wall PET Bottles provide superior insulation, making them particularly valuable for products sensitive to temperature changes. Temperature fluctuations during storage or transit can negatively impact certain products, especially in the food and cosmetics industries. For example, certain cosmetic formulations can degrade or lose effectiveness when exposed to high temperatures, while food items may spoil if subjected to freezing or extreme heat. The thicker walls of PET bottles provide an additional layer of insulation, slowing down the transfer of heat or cold to the contents inside. This insulation helps stabilize the internal temperature of the bottle, minimizing the risk of damage due to temperature changes. In scenarios where bottles are exposed to cold environments, such as in refrigerated transport or storage, the added thickness helps keep the internal temperature stable and reduces the risk of freezing. Conversely, in warm environments, the thicker walls offer better resistance to heat and help maintain product integrity. By using advanced blow molding techniques and high-quality raw materials, Shaoxing Lizhi Plastic Products Co., Ltd. ensures that their Thick Wall PET Bottles have superior thermal resistance, offering a level of protection that traditional single-wall bottles cannot provide. This makes them ideal for products that require temperature-controlled conditions for optimal performance.

Thick Wall PET Bottles also excel in protecting contents from environmental factors such as moisture, air, and UV rays. These factors can have detrimental effects on the quality and shelf life of the product inside, particularly in the case of cosmetic products, food, and pharmaceuticals. Exposure to moisture and air can lead to oxidation, degradation, and contamination, while UV rays can cause fading, discoloration, and a reduction in product efficacy. To address these concerns, Shaoxing Lizhi Plastic Products Co., Ltd. employs multi-layer blow molding technology that enhances the barrier properties of their Thick Wall PET Bottles. Multi-layer technology involves creating bottles with multiple layers of material, each layer serving a distinct function, such as preventing moisture ingress, blocking UV radiation, and offering additional protection against physical stress. For example, by incorporating materials such as EVOH (Ethylene Vinyl Alcohol) into the PET bottle, these multi-layered bottles offer a significant improvement in oxygen barrier properties, which is especially beneficial for products sensitive to oxygen exposure. The additional layers also provide a higher degree of UV protection, preventing harmful light from degrading sensitive ingredients. By combining the benefits of thick PET walls with multi-layer technology, Shaoxing Lizhi Plastic Products Co., Ltd. produces bottles that offer an enhanced level of protection, ensuring the contents remain safe from the damaging effects of environmental exposure.

Light, particularly UV (Ultraviolet) radiation, is one of the most common causes of product degradation, particularly for sensitive products like skincare items, perfumes, and even some pharmaceuticals. UV radiation can cause chemical reactions that break down active ingredients in these products, leading to a reduction in efficacy, discoloration, or even the formation of harmful compounds. Thick Wall PET Bottles are particularly effective at blocking UV light due to their increased thickness. The material’s density and structure prevent light from penetrating the bottle and reaching the product inside. In industries such as cosmetics, where the preservation of ingredient integrity is critical, UV protection is an essential feature of the packaging. Shaoxing Lizhi Plastic Products Co., Ltd. understands the importance of light protection and utilizes multi-layer technology to provide additional UV-blocking layers in their Thick Wall PET Bottles. These advanced bottles can significantly reduce the amount of UV light that penetrates the packaging, offering an extra layer of defense to prevent product degradation.

Beyond the basic physical and environmental protection offered by Thick Wall PET Bottles, the enhanced strength and durability of these bottles contribute to consumer safety. For example, in the food and beverage industry, where products may contain liquids under pressure or need to be sealed to maintain freshness, a thicker PET bottle reduces the risk of leakage or contamination during storage and use. The strong, secure seals provided by Thick Wall PET Bottles also minimize the chances of tampering or accidental opening. This is particularly crucial in markets where product security is a significant concern, such as in the pharmaceutical industry. With a thicker material structure, the bottle is more resistant to attempts at tampering and more capable of maintaining an airtight, leak-proof seal. The bottles are often designed with child-resistant caps and tamper-evident features, further enhancing the safety and security of the product inside. These features are essential in ensuring that the product reaches the consumer in its intended form and remains safe for use.

The thicker walls of PET bottles play a critical role in preserving the shelf life of products by maintaining internal conditions that are more stable than those in thinner-walled bottles. In the case of food, beverages, and cosmetics, a stable environment is necessary to prevent spoilage and to ensure that the product maintains its intended texture, fragrance, and effectiveness. Shaoxing Lizhi Plastic Products Co., Ltd.’s use of advanced blow molding techniques ensures that the Thick Wall PET Bottles are not only strong but also provide an optimal internal environment that helps extend product freshness. By preventing exposure to environmental factors such as oxygen, moisture, and UV light, these bottles effectively reduce the likelihood of product degradation, ensuring that customers receive high-quality products with longer shelf lives.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français