Company

Shaoxing Lizhi Plastic Products Co., Ltd.

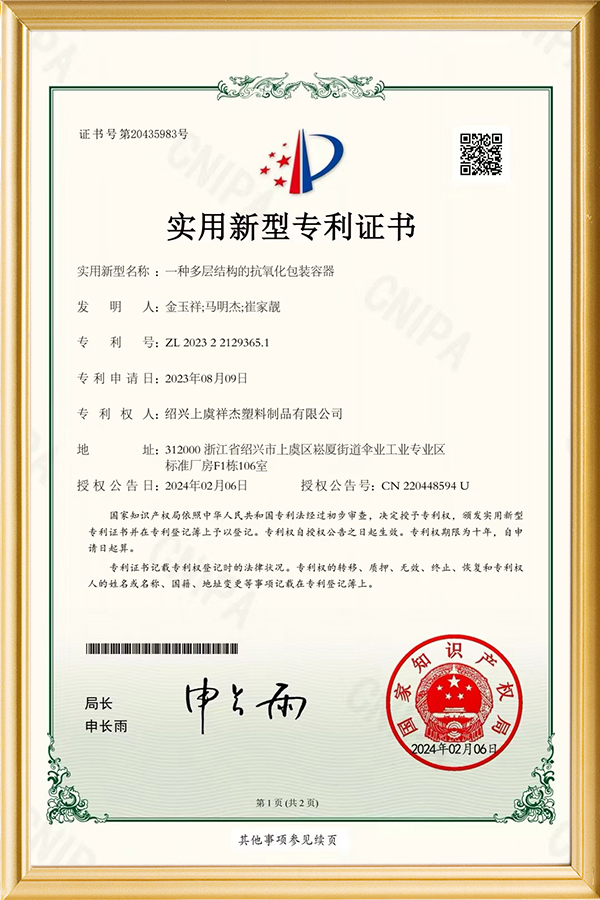

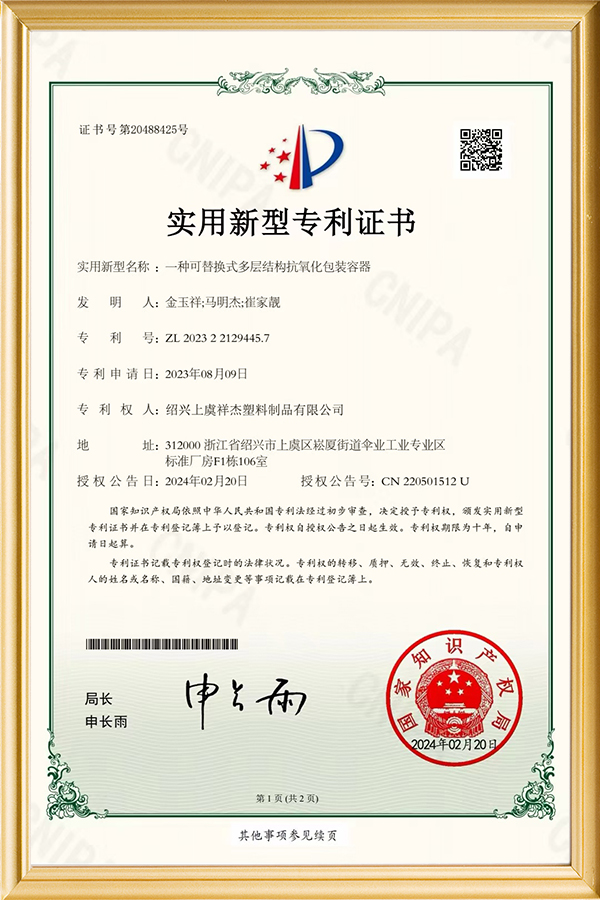

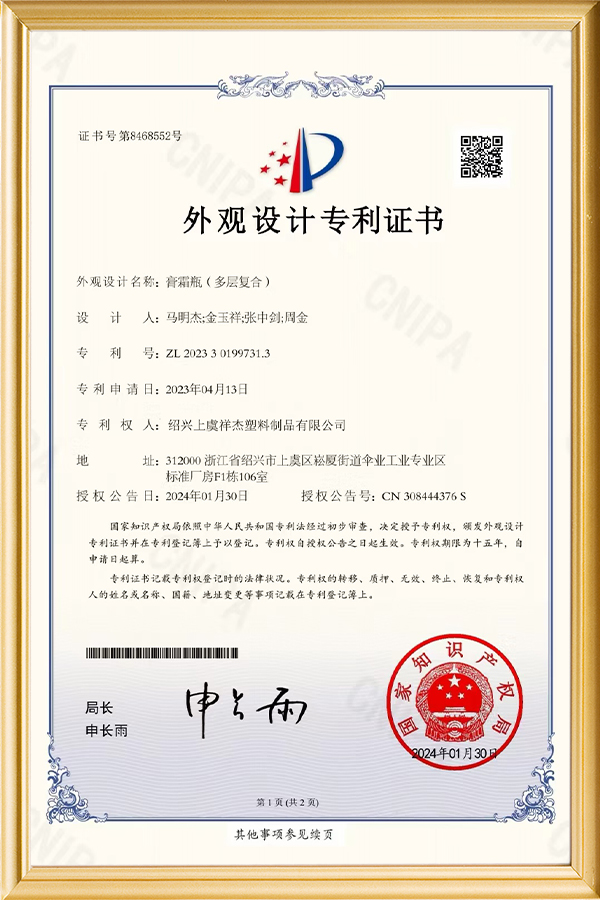

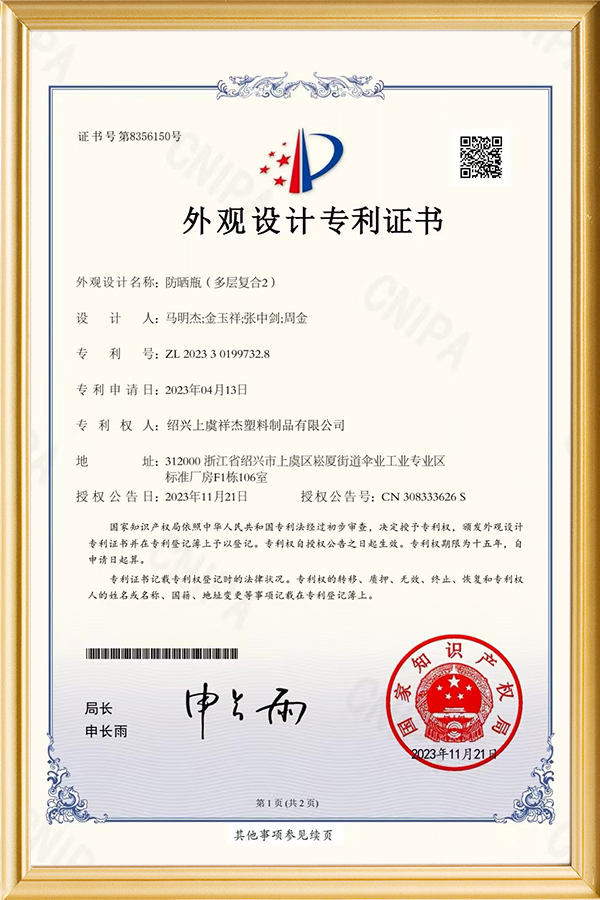

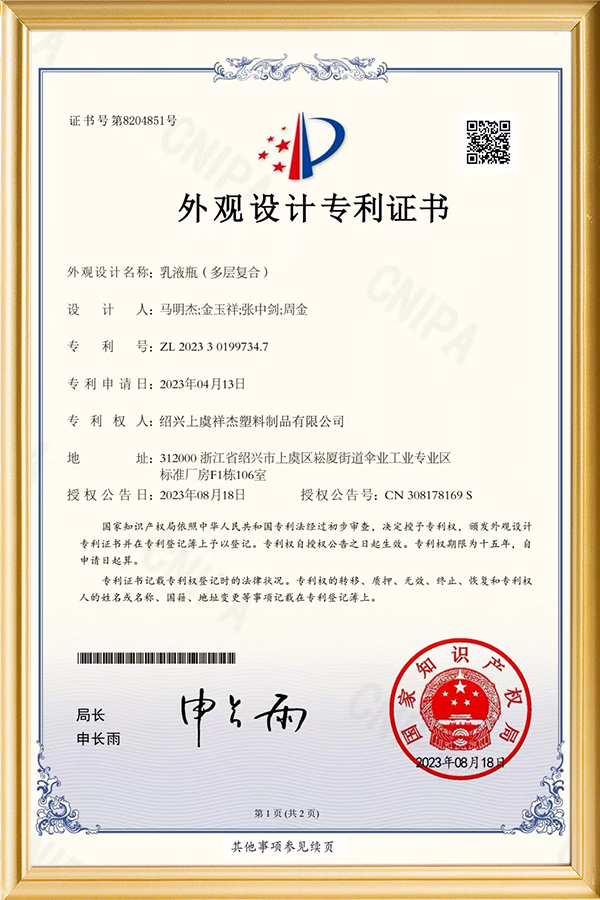

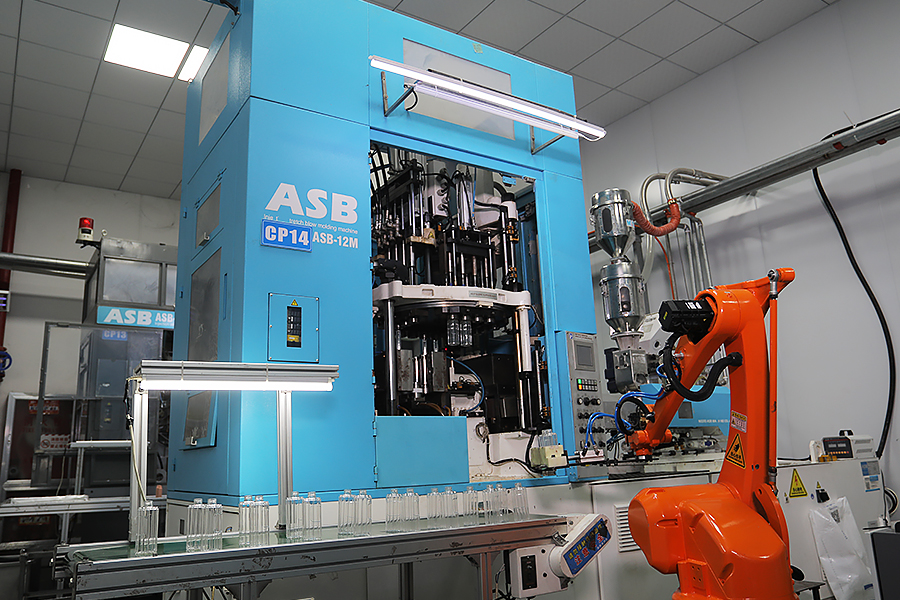

As a famous China PE Sunscreen Bottle Manufacturers and Empty Sunscreen Bottle Series Factory, Shaoxing Lizhi Plastic Products Co., Ltd. is deeply engaged in the field of cosmetics packaging. It relies on high-end Japanese imported machinery and equipment, applies advanced single-layer and multi-layer blow molding technology, and uses raw materials such as PP/PE/PET/PETG/EVOH to ensure that the products not only show high-end texture, but also meet the expectations of modern consumers for safety, harmlessness and freshness.

News

-

As the global travel industry continues to thrive, a significant shift has occurred in how consumers choose their personal care products. Modern travelers are n...

READ MORE -

When it comes to protecting your skin from the sun’s harmful UV rays, using sunscreen is a must. However, applying sunscreen effectively is just as important as...

READ MORE -

In recent years, there has been a noticeable shift in the skincare industry, with more consumers seeking packaging solutions that are both efficient and environ...

READ MORE -

In today’s personal care market, consumers are paying closer attention not only to skincare formulas but also to the packaging that holds them. Bottles and cont...

READ MORE

Industry Knowledge Expansion

How Sunscreen Lotion Bottles Protect Product Freshness

One of the most critical factors in maintaining the freshness of sunscreen is preventing its exposure to air. When sunscreen lotion bottles are opened and closed, air enters the bottle, leading to oxidation, which can cause the active ingredients, particularly chemical UV filters, to break down. This breakdown results in a reduction in the effectiveness of the sunscreen, making it less reliable for UV protection. To prevent oxidation, it is essential to have a well-designed airtight packaging solution. Shaoxing Lizhi Plastic Products Co., Ltd. uses tamper-evident caps and tightly sealed closures to create airtight packaging for sunscreen lotions. These airtight seals play a significant role in preventing air from entering the bottle after it has been sealed. This helps to protect the sunscreen from oxidation, ensuring that the formula remains intact and effective for a longer time. The company’s advanced manufacturing techniques, such as precision blow molding and injection molding, allow for a consistent seal that prevents leaks or spills. This airtight design is essential not only for preserving the product but also for enhancing the convenience of the consumer. The secure closures also reduce the risk of contamination by external pollutants, such as dust or bacteria, ensuring that the sunscreen remains safe for use throughout its shelf life. By minimizing exposure to air, Shaoxing Lizhi Plastic Products Co., Ltd. ensures that the product stays fresh and effective, enhancing its performance and shelf life.

The materials used in sunscreen lotion bottles must provide effective barriers against environmental factors such as oxygen, moisture, and light. These elements can degrade the quality of the sunscreen, reducing its effectiveness and safety. To combat these threats, Shaoxing Lizhi Plastic Products Co., Ltd. utilizes advanced multi-layer blow molding technology. Multi-layer bottles are constructed with several layers of material, each serving a specific function. The outer layer of the bottle provides structural integrity, ensuring that the bottle is durable and resistant to physical damage. The inner layers, however, play a more vital role in protecting the product inside. For example, an inner layer made from EVOH (ethylene vinyl alcohol) creates an excellent barrier against oxygen, preventing oxygen from reaching the sunscreen. Since oxygen can degrade the active ingredients in sunscreen, this barrier is essential for preserving the product's potency. Similarly, the use of polyethylene (PE) and polypropylene (PP) in the bottle's layers provides resistance against moisture, further safeguarding the formula. Moisture can cause the sunscreen to lose its texture, leading to clumping or separation of ingredients. The multi-layer design ensures that external factors such as oxygen and moisture do not penetrate the packaging, keeping the sunscreen formula intact and fresh. Multi-layered bottles also offer greater strength and flexibility, which reduces the risk of the bottle being compromised by external forces, such as squeezing, dropping, or pressure changes. This design ensures that the sunscreen remains stable, fresh, and effective for a more extended period.

Exposure to UV light is one of the most significant factors in the degradation of sunscreen products. UV rays can break down the active chemical filters used in sunscreen, reducing their ability to protect the skin from harmful UV radiation. Sunscreen lotion bottles must be designed to block UV light to prevent the product inside from being compromised. Shaoxing Lizhi Plastic Products Co., Ltd. recognizes the importance of UV protection and, therefore, uses materials such as PET and PETG in the production of their sunscreen lotion bottles. These materials are inherently UV-resistant, providing an additional layer of protection to the sunscreen formula. PET and PETG are not only durable and lightweight but also offer excellent resistance to UV radiation, ensuring that harmful rays cannot penetrate the bottle and degrade the product inside. This UV protection is particularly critical for sunscreens that are stored outdoors or on retail shelves under bright lighting. Without proper UV protection, sunscreen could lose its effectiveness, making the product unreliable. By using UV-resistant materials, Shaoxing Lizhi Plastic Products Co., Ltd. ensures that the sunscreen remains potent and effective, even when exposed to sunlight or artificial lighting during transportation and storage. UV protection prevents the breakdown of active ingredients, which helps maintain the sunscreen's quality and efficacy throughout its shelf life.

Moisture can have a detrimental effect on sunscreen products, particularly in the form of contamination or microbial growth. When exposed to moisture, sunscreen formulations can develop bacteria, mold, or fungi, which could affect the product's safety and effectiveness. To prevent moisture from entering the bottle, Shaoxing Lizhi Plastic Products Co., Ltd. uses materials like PP, PE, and PET, which are highly moisture-resistant. These materials ensure that the sunscreen stays dry and protected from water and humidity, both of which can cause the formula to deteriorate over time. Furthermore, Shaoxing Lizhi Plastic Products Co., Ltd. incorporates hygienic dispensing mechanisms, such as pumps, flip-top caps, and squeezable tubes, into their bottle designs. These features prevent consumers from directly touching the product or introducing moisture into the bottle, reducing the risk of contamination. Pumps, for instance, allow for a controlled and hygienic application of the sunscreen, without the need to touch the bottle’s contents. Similarly, flip-top caps and squeezable tubes ensure that the product can be dispensed with minimal risk of introducing moisture. By preventing moisture contamination, Shaoxing Lizhi Plastic Products Co., Ltd. ensures that the sunscreen product remains safe, hygienic, and effective. This focus on moisture resistance helps to extend the product's shelf life while maintaining the integrity of the sunscreen formula.

Sunscreen lotion bottles must strike a balance between being lightweight for portability and being sturdy enough to withstand physical impacts. Sunscreen products are often used outdoors, making it essential for the packaging to be easily portable while remaining durable. Shaoxing Lizhi Plastic Products Co., Ltd. achieves this balance through the use of advanced blow molding technology. This technology allows the company to create lightweight bottles that are still strong and resistant to impact. The lightweight design makes the bottles easy to carry, whether for a day at the beach, hiking, or traveling. Despite their reduced weight, these bottles maintain their strength and can withstand moderate physical stress, such as drops or pressure from squeezing. This durability ensures that the sunscreen remains safe inside the bottle and that the packaging does not get damaged easily. The ergonomic design of the bottles further enhances portability, making it easy for consumers to carry them without feeling burdened by the weight of the packaging. By focusing on strength without sacrificing weight, Shaoxing Lizhi Plastic Products Co., Ltd. provides packaging that is both functional and convenient for everyday use.

Tamper-evident packaging is essential for maintaining the freshness and safety of sunscreen products. Sunscreen lotions are frequently used on the skin, and consumers expect packaging that ensures the product is untouched and safe for use. Tampering with sunscreen products can not only compromise the freshness of the formula but also introduce harmful bacteria or contaminants. To ensure consumer safety, Shaoxing Lizhi Plastic Products Co., Ltd. integrates tamper-evident features into their sunscreen lotion bottles. These features, such as tamper-evident seals, caps, and closures, help reassure consumers that the product they are purchasing has not been previously opened or altered. When the seal is broken, it is immediately apparent, making it clear that the bottle has been tampered with. This level of protection is particularly important for skincare products, where maintaining product integrity is crucial for both safety and efficacy. The use of tamper-evident packaging also prevents accidental spills or leaks during transportation, ensuring that the product arrives safely at its destination. By incorporating these features, Shaoxing Lizhi Plastic Products Co., Ltd. helps to maintain the product's freshness and quality, providing consumers with a high level of confidence in the products they purchase.

Subscribe to us and

get the latest updates.

get the latest updates.

Stay In Touch

English

English 中文简体

中文简体 Français

Français